ASICS

Japanese sportswear brand ASICS is building the foundation for its personalization services upon the industry solution experiences Perfect Consumer Product and Perfect Product Staging. The 3DEXPERIENCE platform on the cloud allows ASICS to showcase less visible parts of its products to consumers so that they can make informed purchase decisions.

Personalized shoes for all

In the near future, customers will be able to purchase shoes from ASICS stores that perfectly fit their feet. This is one of ASICS’ long-term visions, achieved through digital, personal, and sustainable product development, to support people to live healthy and active lives.

Kihachiro Onitsuka founded ASICS on the belief that physical activity inspires positive mental well-being. One of the company’s first innovations was the suction cup sole on basketball shoes, which gave players more grip on the court. While the introduction of an air vent system in marathon runners’ shoes helped to enhance breathability, release heat, and prevent blisters.

ASICS’ product development is rooted in human-centric science. It studies users’ physical characteristics and movements and takes advantage of digital simulation for structural and material design. Athletes then test the products in the field to make sure they meet their needs. Recently, ASICS is exploring the potential of mass customization. The company plans to offer the same level of service it provides to professional athletes to all its customers.

“No two people have the same foot shape,” said Genki Hatano, lead researcher in the Green Manufacturing Research Team, Future Creation Dept., ASICS Institute of Sport Science (ISS). “Diverse customer needs across different sports require us to transform the way we make our products so they are truly personalized. High-functional running shoe models already come in many variations. Now, to provide all our customers with products that deliver a new level of comfort and satisfaction for both mind and body, we are considering more customization options, such as foot beds that support the underside of the foot, and customizable shoe components.”

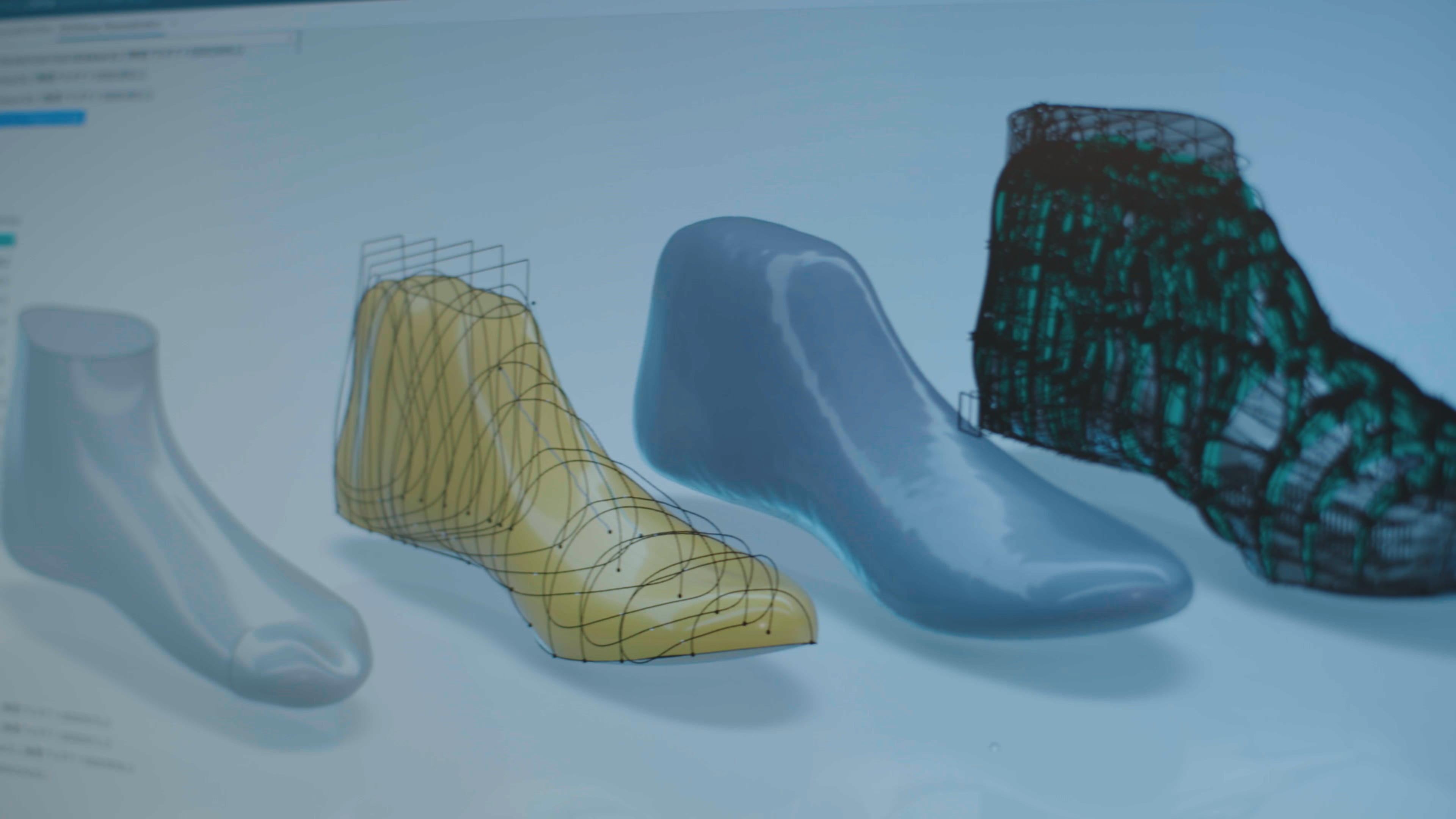

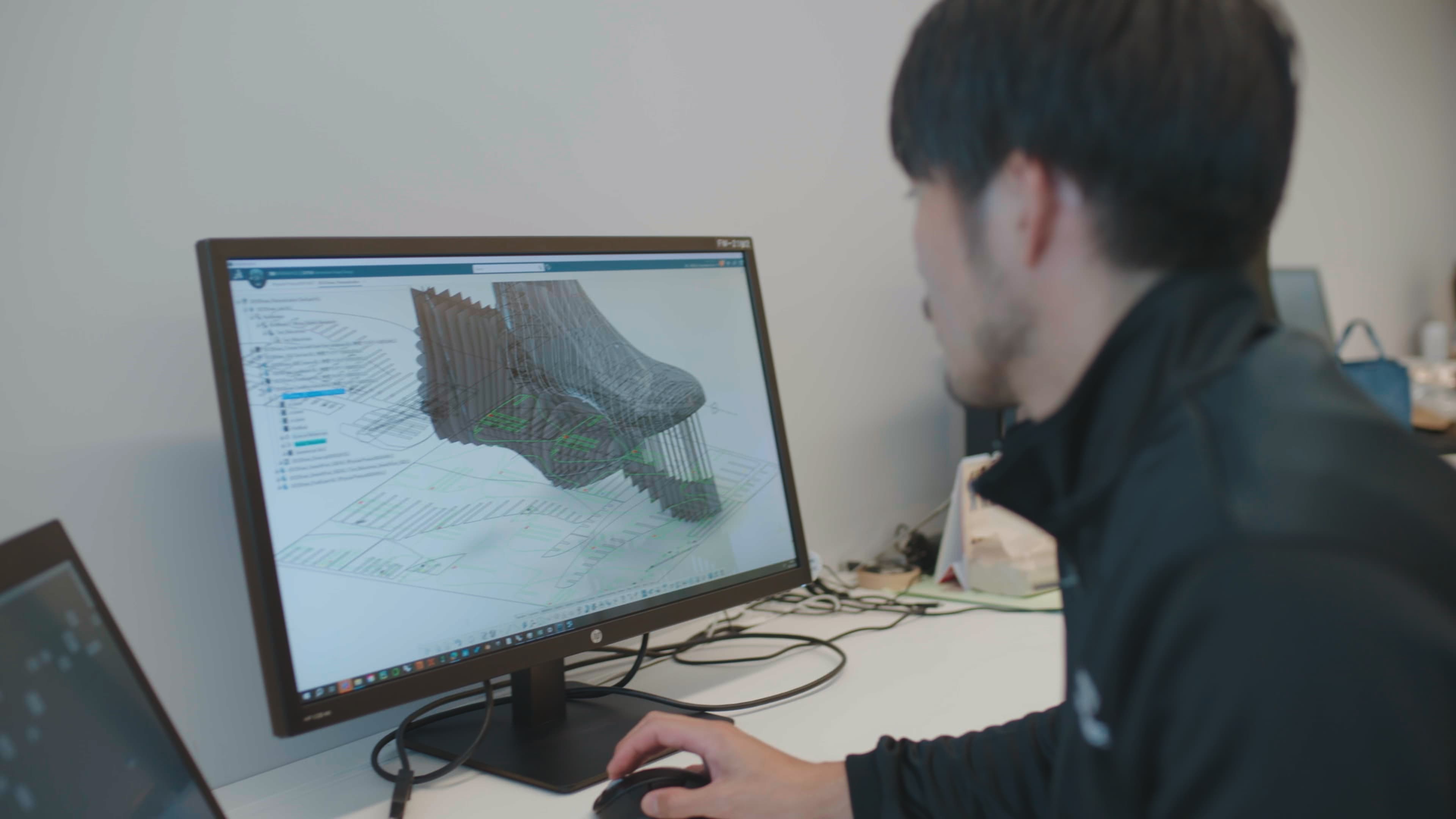

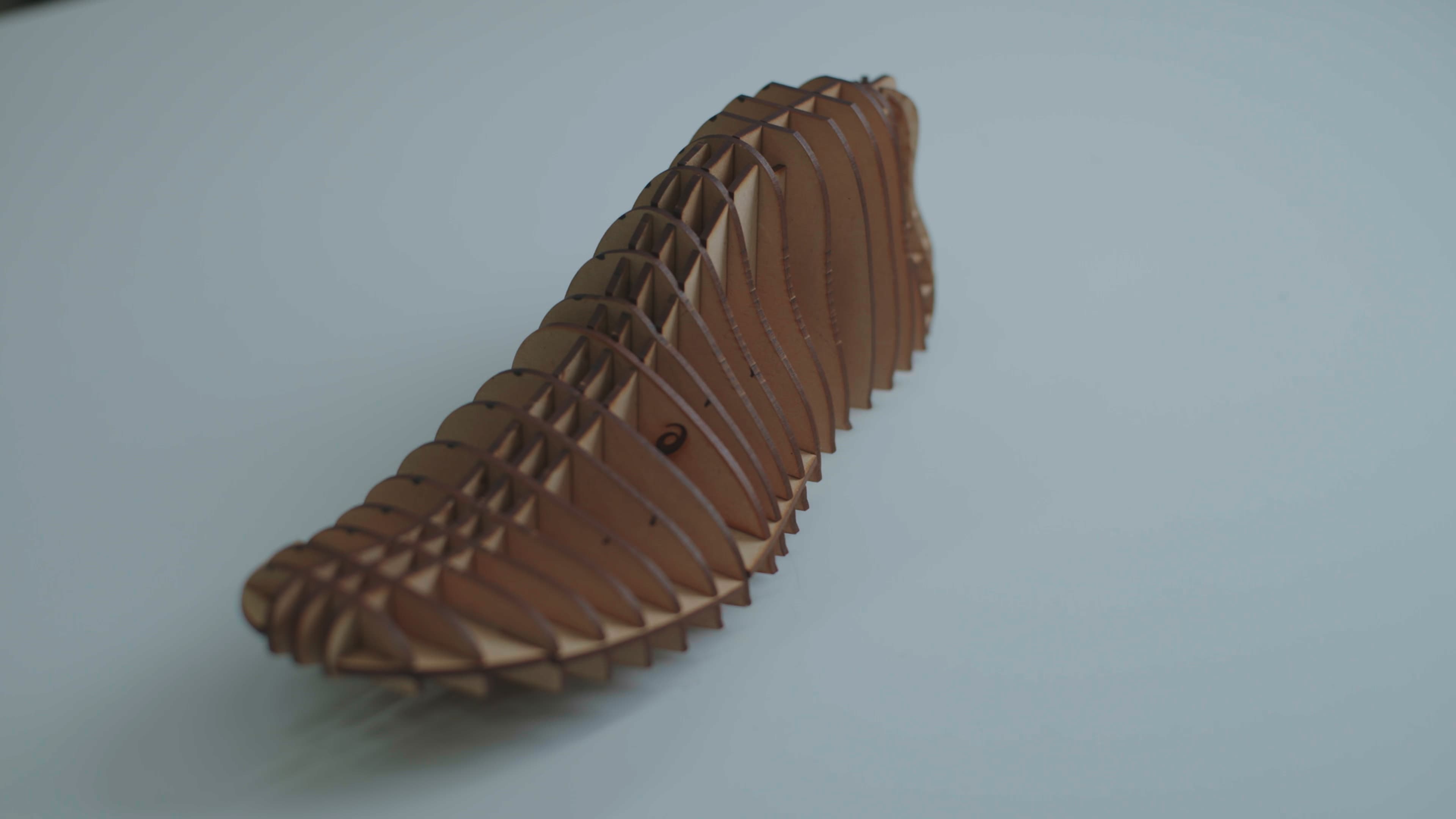

As part of its research and development efforts, ASICS is collaborating with Dassault Systèmes to create new personalization services. In 2021, ASICS introduced a concept for creating personalized shoe lasts at ASICS EXPERIENCE TOKYO, a temporary experiential facility in Harajuku. It used CATIA on the 3DEXPERIENCE platform on the cloud to develop and manage the entire process.

CATIA’s advanced modeling capabilities were instrumental for creating highly accurate surfaces and maintaining a seamless data flow from one development stage to the next. Using the CAD solution, ASICS was able to quickly and easily adjust designs to suit each customer.

The 3DEXPERIENCE platform captured all the information we needed and ensured a consistent data flow from one stage to the next.

Customization in store

Renowned for highly functional products that enhance athletic performance, ASICS aims to create shoes that perfectly fit every user’s feet, preferences, and running style, ultimately increasing comfort and reducing the risk of injuries. To this end, the company developed an interactive experience for custom sock liners – managed on the 3DEXPERIENCE platform on the cloud.

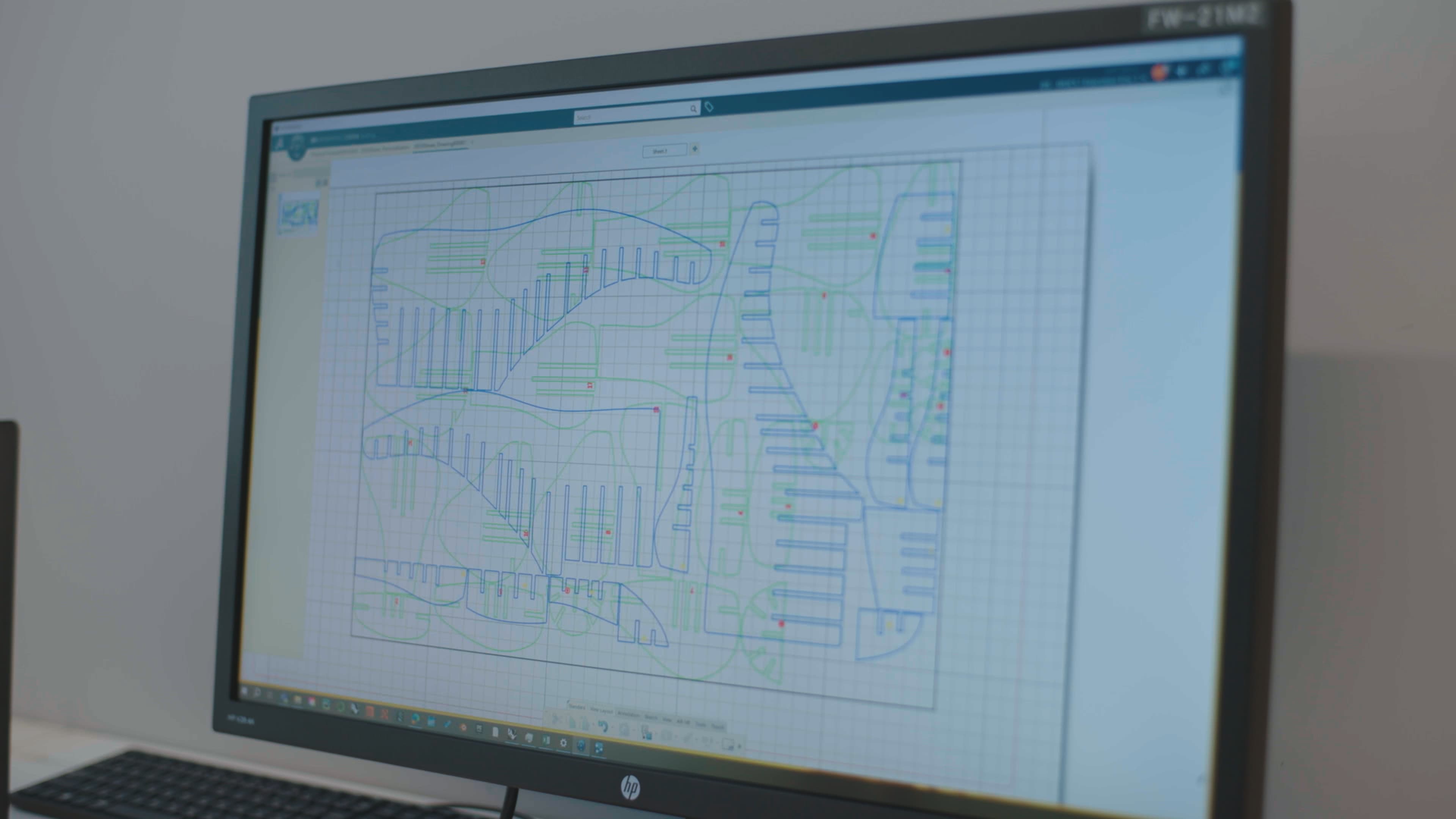

In 2022, to commemorate the fifth anniversary of ASICS’ Harajuku flagship store, customers had the unique opportunity to get their feet 3D scanned. The scan data was turned into a 3D model, used to automatically design their own sock liners for a pair of running shoes. Customers were given three sock liner options to choose from: a “best fit” option and two alternatives with different levels of cushioning.

“We needed to serve a large number of people in an extremely short amount of time, so it was essential that we could automate the process by feeding the customers’ data into an algorithm,” Hatano said. “The 3DEXPERIENCE platform captured all the information we needed and ensured a consistent data flow from one stage to the next.”

Customers enjoyed the process of making their products. The virtual experience really resonated with them; they felt that it was more enriching than simply receiving the physical product.

Interactive and engaging user experience

For ASICS, services like these not only provide customers with personalized products that help improve their performance. They’re also a chance to offer an exciting, new in-store experience. The virtual experience added a new dimension to simply trying on physical products, helping customers make informed purchase decisions and understand more about parts of the product they’d perhaps not otherwise notice.

“We really thought about the experience we were offering to our customers,” said Norihiko Taniguchi, general manager of the Future Creation Dept., ASICS ISS. “In this instance, customers enjoyed the process of making their products. The virtual experience really resonated with them; they felt that it was more enriching than simply receiving the physical product. We received a lot of positive feedback.”

ASICS used 3DEXCITE to bring the 3D models of the sock liners to life in a realistic manner and make them visible to customers. This clear visual representation helped them better understand how a personalized sock liner could enhance foot support and improve comfort when wearing their shoes.

“Using color mapping on the 3D model to show customers various sock liner options helped to deepen their understanding of the technical aspects of the products and better understand why a particular shape worked for them,” Hatano said. “They could compare various styles and see how it would affect their feet. Customers made comments such as, ‘I’d prefer this option,’ and ‘This personalized version suits me better.’ The 3D model was a valuable tool for communicating different product characteristics and supporting customers to make informed decisions before purchase.”

Security is also extremely important when dealing with personalized products, and with the 3DEXPERIENCE platform’s cloud environment, we can be sure our data is safe.

Cloud-powered seamless research and development

Even before introducing its new personalization services, ASICS could see the value of using the 3DEXPERIENCE platform on the cloud. The project teams involved at the product development stage could collaborate, seek answers to questions, and resolve issues seamlessly on the platform.

“The cloud platform allowed engineers from around the world to communicate, which facilitated quick issue resolution and smooth product development,” said Shingo Takashima, manager of the Virtual Twin Research Team, Future Creation Dept., ASICS ISS. “Security is also extremely important when dealing with personalized products, and with the 3DEXPERIENCE platform’s cloud environment, we can be sure our data is safe. We also benefit from constantly updated features as we continue to evolve as a company.”

Storing all product development data in the cloud helps keep projects on track, and allows globally dispersed teams to easily access all the information they need. ASICS’ office in Boston, responsible for deciding which products to launch based on market research, has trialed the 3DEXPERIENCE platform for reviewing the latest shoe models in collaboration with ASICS ISS in Kobe.

“For example, when developing the long-distance running shoe GEL-KAYANO LITE, our engineering team in Kobe posted progress in the 3DEXPERIENCE platform community,” Takashima said. “We carried out reviews with the team in Boston and could keep track of all modifications with a full version history. The 3DEXPERIENCE platform was extremely advantageous as it allowed everyone to work with the same data and keep the project progressing through the day and night across time zones. Effective communication was possible, and we could create something entirely new very quickly and efficiently.”

The 3DEXPERIENCE platform on the cloud delivers the flexibility ASICS needs to roll out new services around the world. ASICS is currently focused on further enhancing its user experiences by improving the quality of its parametric modeling. It is also taking meaningful steps to become a more sustainable business.

“The 3DEXPERIENCE platform allows us to monitor not only the shape and performance of the product but also its impact on the environment, helping us set sustainability goals,” Takashima concluded. “It helps us consider how data can be linked to the way we manufacture our products. Dassault Systèmes is a partner that motivates us. We look forward to working together in the future, particularly for achieving our carbon neutral targets, and exploring the potential of the virtual twin to improve our product design and the way we communicate with our customers. ASICS believes that, together with Dassault Systèmes, we can create a happier and healthier society. I really feel like we’re creating something new together.”

Discover more about the Perfect Product Staging and Perfect Consumer Product industry solution experiences.

Focus on ASICS

ASICS’ founding philosophy, “Anima Sana In Corpore Sano,” which means “A Sound Mind in a Sound Body,” expresses the brand’s desire for people worldwide to live healthy and happy lives, both physically and mentally. ASICS has formulated its long-term vision, “VISION 2030,” and is expanding its business in three domains: “Product,” “Facility and Community,” and “Analysis and Diagnosis.” By using evolving digital technologies, ASICS develops and provides personalized products and services tailored to each customer, employing environmentally conscious, sustainable methods.

For more information: https://corp.asics.com