Ascendance Flight Technologies

Focused on clean and sustainable aviation, the French startup needed an industry platform to support and accelerate the development of Atea, a vertical takeoff and landing (VTOL) aircraft equipped with a hybrid electric propulsion system, Sterna. To bring its hybrid eVTOL technology to market, the company is using the cloud-based solution Reinvent the Sky on the 3DEXPERIENCE platform to manage systems engineering, product design and governance.

Scaling hybrid eVTOL tech for sustainable aviation

There has been a great deal of talk about making aviation more sustainable in the future. Yet, for the founders of Ascendance Flight Technologies, meaningful and realistic change must happen sooner. Drawing from their experience working on electric aircraft at major aerospace companies, the engineers are now in the process of developing their own hybrid energy aircraft technology – something they believe is a faster and more practical route to low carbon flight.

“We set up Ascendance Flight Technologies with a clear vision of what we wanted to achieve: to accelerate the transition towards more sustainable aviation through hybrid electric technology,” said Jean-Christophe Lambert, co-founder and CEO of Ascendance Flight Technologies. “Protecting our planet is a top priority and we want to allow people and goods to freely circulate without harming it.”

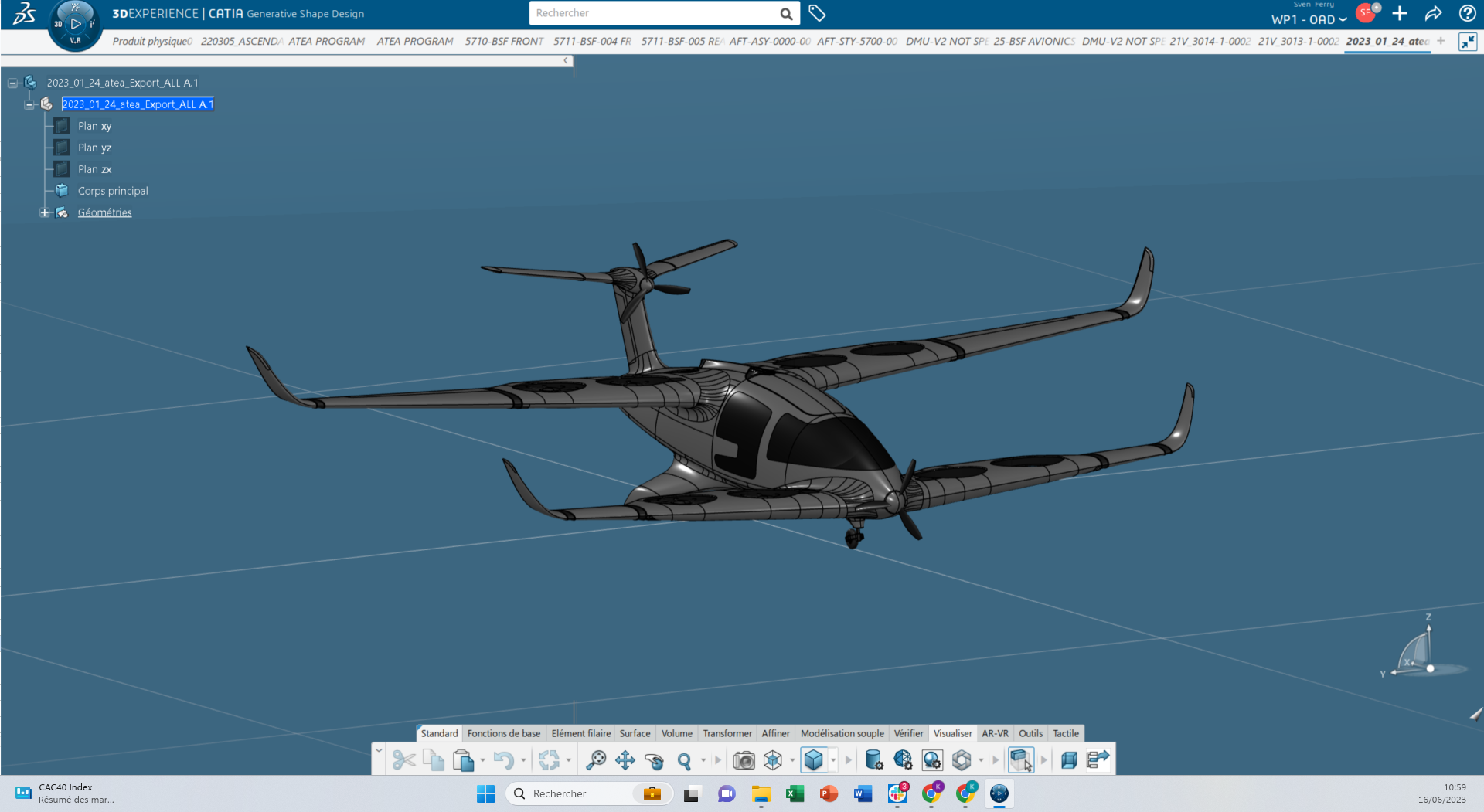

Plans are on track for Atea, the five-seater hybrid electric vertical takeoff and landing (VTOL) aircraft to go into production by 2025 and enter into service as soon as 2026. Designed for local and regional flights, Atea will have a 400-kilometer range and cruising speed of at least 200 kilometers per hour – ideal for passenger transportation, logistics, emergency medical services and surveillance. Its lift-plus-cruise architecture features ducted fans, uniquely integrated into the front canards and main wings for vertical takeoff. When in flight, it will emit up to 80% fewer carbon emissions and be four times quieter than conventional, gas-powered helicopters.

Atea is also the first use case for the French startup’s hybrid electric propulsion technology called Sterna, which will roll out on a wider scale in commercial aircraft. The company’s proprietary hybrid engine merges combustion and electric energy to power Atea through the air. Later on, Ascendance Flight Technologies will phase out combustion for cleaner energy sources such as hydrogen.

“Atea is the ideal low-carbon solution for local and regional travel today,” said Benoit Ferran, co-founder and CTO of Ascendance Flight Technologies. “Its hybrid electric propulsion will significantly reduce fuel burn. The fact it mixes twin energies is a big differentiator as it supports the range, payload and speed our potential customers require.”

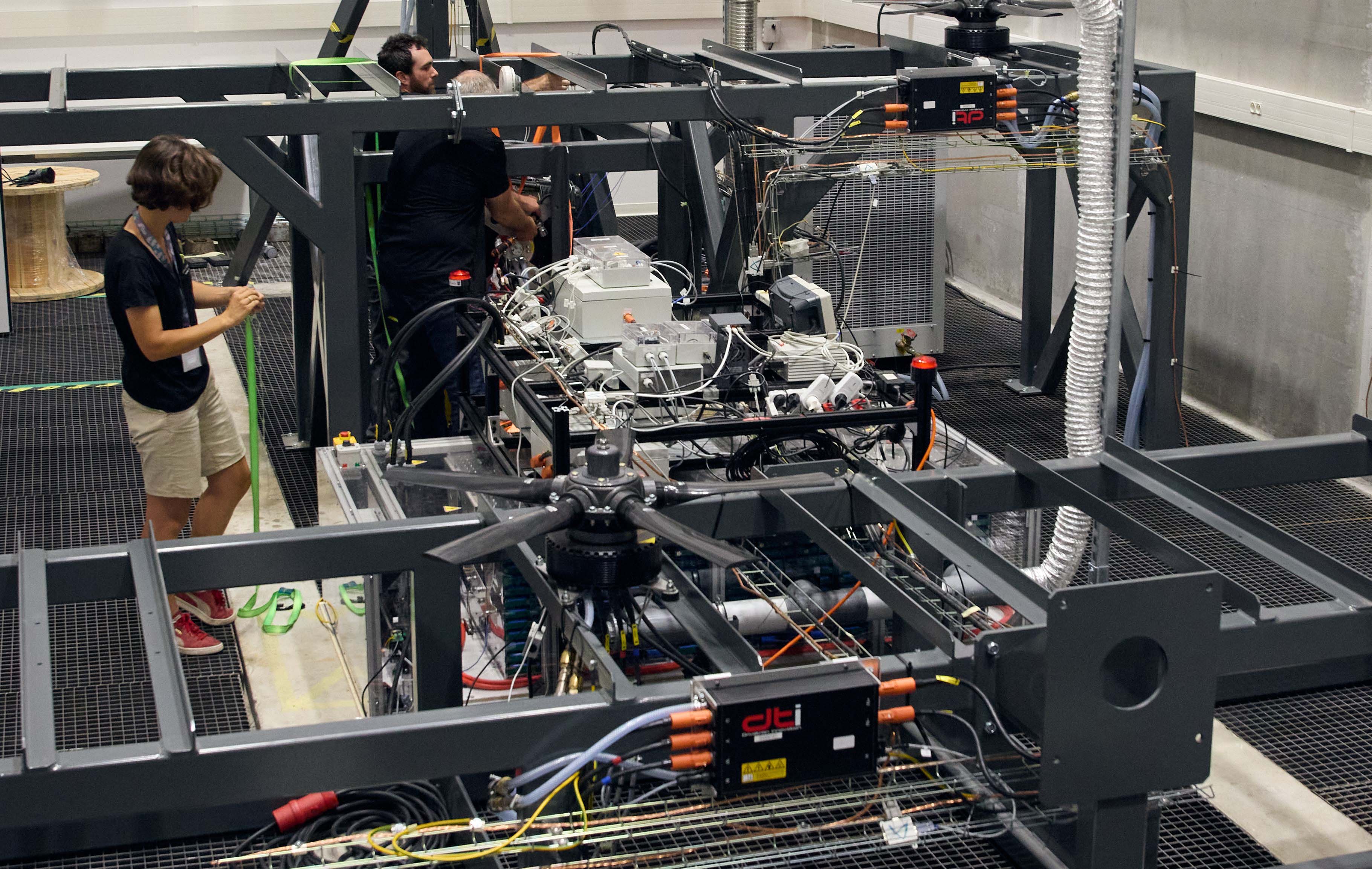

With funding secured to move to the next development stage, Ascendance Flight Technologies is now building the first full-scale prototype of Atea and is on its way to certification with the European Union Aviation Safety Agency (EASA). The company is able to move at such speed thanks to its drive, expertise and clear roadmap, as well as its industry platform – 3DEXPERIENCE® on cloud.

“Coming from Airbus, we were familiar with Dassault Systèmes and the 3DEXPERIENCE platform,” Ferran said. “They help us to connect all facets of our product development and manage the innate complexities that come with being a fast-growing business. It has been a huge accelerator for us.”

Bringing structure to the startup

Initially, Ascendance Flight Technologies accessed Dassault Systèmes’ solution through the 3DEXPERIENCE for Startups program. The initiative gets behind fledgling companies by making enterprise-level IT affordable and providing all the associated support they need to get their business off the ground quickly.

“The initial low cost of the platform and comprehensive support were invaluable to us,” Ferran said. “Dassault Systèmes’ team advised us on the best way to use the platform for building our first prototype and they really got involved int helping into our systems engineering and structure before everyone jumped in and got started. Then it was about supporting us to add and use more functionalities as we progress further along the development cycle.”

As well as offering up its industry expertise, Dassault Systèmes also delivered all the necessary online training to the engineering team to ensure they get the most from the 3DEXPERIENCE platform.

“Though the solution is intuitive and the learning curve is fast, it’s been very helpful to have the additional training to get the platform well integrated into the team and how we work,” Ferran said. “It’s really allowed us to standardize our methods.”

Dassault Systèmes helps us to connect all facets of our product development and manage the innate complexities that come with being a fast-growing business. It has been a huge accelerator for us.

Developing designs built to fly

Atea is the result of years of research and development and has gone through multiple design iterations to create the hybrid energy aircraft its founders envisioned. Today’s concept – a sleek and futuristic looking canard configuration aircraft featuring distinctive fan-in-wing technology – is the one Ascendance Flight Technologies plans to certify and launch to market. It’s a bold departure from the traditional high-wing monoplane concept that Ascendance Flight Technologies first unveiled. Additional ducted fans and propellers increase the power available during takeoff and landing, improve redundancy and enhance maneuverability in flight. This should make it easier to certify under EASA’s new VTOL rules. Ascendance Flight Technologies carried out all design work using the full functionality of CATIA on the 3DEXPERIENCE platform.

“CATIA has been key for creating the very complex aerodynamic shapes,” Ferran said. “The way you can build the shape of your curves is really efficient. And as we’ve refined the design of the aircraft, we’ve had to perform a lot of trade-offs. CATIA allowed us to fix the outer lines of the aircraft, including the aerodynamic shapes, so we can work around them and look at how to integrate all the systems.”

Atea’s audacious design has garnered the company backing from some of the industry’s leading experts. Ferran explained the integral role of the 3DEXPERIENCE platform in demonstrating their professionalism and ability to innovate.

“When you’re trying to get investment and prove everything is progressing as it should, then the fact that we have all of our ideas and design concepts formalized in the platform really gives us confidence,” he said. “The 3DEXPERIENCE platform on cloud has baselined our processes and harmonized them. It means we can give our engineers all the freedom they need to innovate while still working within the boundaries we’ve set.”

Compliance with aviation regulations

From the outset, Atea has been designed to comply with the latest EASA regulations. Ascendance Flight Technologies works closely with the regulatory authorities to help define vehicles flight rules while ensuring the company’s own internal processes meet these requirements to accelerate time to market.

“We must demonstrate compliance at every stage and produce all the necessary reports and we’ve found the 3DEXPERIENCE platform on cloud really effective for doing that,” Ferran said. “It’s collaborative, it coordinates everyone, and it gives us full traceability so we can tell the certification authorities exactly where we are.”

Ascendance Flight Technologies uses ENOVIA on the platform for certification engineering. Change and configuration management are critical capabilities that allow the company to maintain a common digital thread from one stage to the next and clearly see the effect of any changes within context of the entire 3D model.

“ENOVIA allows us to build a tree of requirements where everything is interconnected and tracked so that when we make a change, we can identify exactly how it affects the systems and part designs around it,” Ferran said. “We can see the different status of parts and ensure compliance with the validation process. Being able to manage all of this in the platform is priceless. It’s also very efficient for peer reviews as you can send notifications to the appropriate team members for sign off rather than bringing everyone around the table.”

Ready for takeoff

Ascendance Flight Technologies continues to ramp up its operations and is rapidly recruiting new talent to bring Atea and Sterna to market. With strong technical capabilities and processes in place, the company is well positioned to more easily onboard new employees and ensure everyone is working in a consistent manner.

“Every year, we used to revisit our methods to adapt to the new size of the team,” Ferran said. “Now, when you consider how we work on the 3DEXPERIENCE platform and how we first started out, there’s no comparison. We plan to recruit more people over the next few months and we’re confident that no matter how large our organization becomes, we have the right technology to keep us on track.”

Ascendance Flight Technologies values Dassault Systèmes’ industry best practices and sees it as a trusted advisor to help deliver on the company’s long-term vision. Both parties worked closely together to steer the program in the right direction.

“Dassault Systèmes not only provided the solution we needed but also showed us how to use it in the best way, and helped solve issues during the implementation phase,” Lambert concluded. “The next step would be to use the solution to improve product sustainability and take into account our carbon footprint throughout the product development cycle. This is key for the future.”

Discover more about the Reinvent The Sky industry solution experience.

Focus on Ascendance Flight Technologies

Ascendance Flight Technologies is a Toulouse-based company developing Atea, a VTOL aircraft powered by Sterna, its proprietary hybrid electric technology stack. The company provides the technologies to empower aircraft manufacturers to reduce the environmental impact of future aircraft generations. Building on its rich industry expertise, Ascendance Flight Technologies aims to be a leader in designing a new era of sustainable aviation.

For more information: www.ascendance-ft.com