Akaer

In 53 days, Akaer implemented the Engineered to Fly industry solution experience on the 3DEXPERIENCE platform. Now that everybody works in the same environment, accessing a single source of information, Akaer decreased product development time, improved productivity and reduced costs.

High-speed software installation

Software installations can take months, and sometimes even years, to implement. So when Akaer – a Brazilian engineering company serving large customers operating in the aerospace and defense markets – said it wanted to implement Dassault Systèmes’ 3DEXPERIENCE® platform in just two months, it was told it simply wouldn’t be possible.

“I had many different people tell me I was crazy – that there is no way I would get this complete in 60 days,” said Joselito Henriques, vice president of R&D and innovation at Akaer. “In fact, people who had done similar implementations said six months might even be a struggle.”

However, a fast implementation was critical for Akaer: it had a huge project riding on it. “We had just won a significant project with the Brazilian Army that would be kicking off in two months’ time,” Henriques said. “The internal design and engineering teams were in need of a better software environment to work in. I was feeling the pressure to deliver something to them.”

The need for change

Akaer is known for successful delivery. “Our engineering capabilities set us apart from the competition,” said Cesar Silva, Akaer’s president and CEO. “We pride ourselves on our ability to get close to our customers and to solve their biggest problems – problems that can be incredibly complex – through the delivery of complete solutions.”

Over the last three decades, the business has provided high-level engineering services to many OEMs across the globe, working on projects spanning the land, sea and air. It employs around 620 employees spread across sites in Brazil, along with some localized teams at customer premises during the initial phases.

Silva believes Akaer’s expertise is unique. “We have been recognized for our original way of thinking, having been awarded ‘most innovative company’ at the National Innovation Awards for three years running,” he said.

Working with some of the biggest aerospace and defense companies in the world means Akaer usually is tied to its clients’ software environments.

“We work on a wide variety of different projects for many different customers,” said Fernando Ferraz, Akaer’s chief operations officer. “It’s very difficult to establish a consistent way of working because we must use our customer’s tools or solutions. However, when we won this project with the Brazilian Army, we were given the freedom to choose our own tools.”

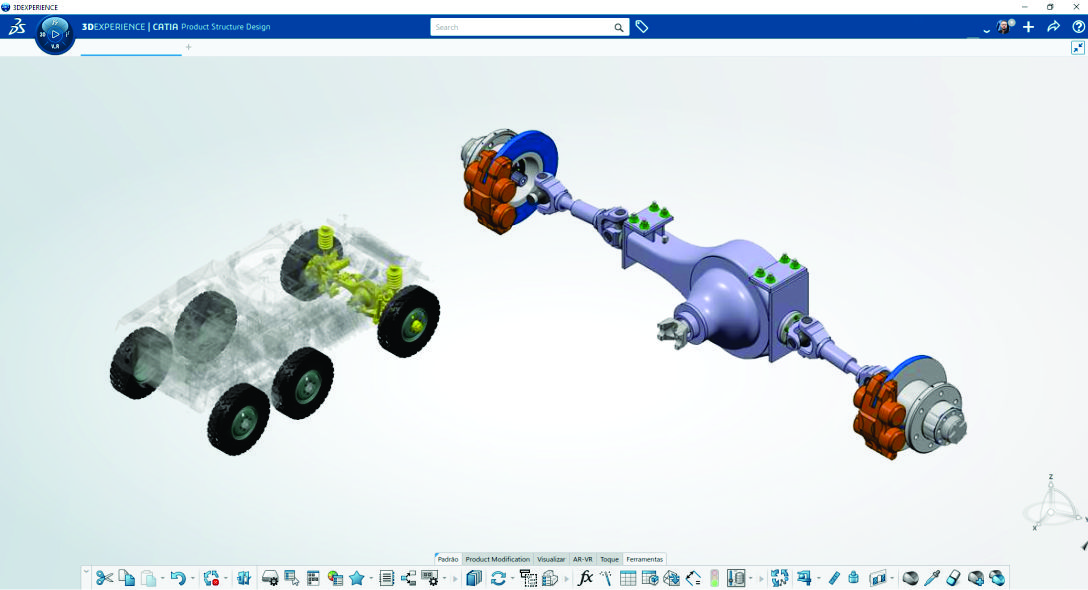

At that point, Akaer used Dassault Systèmes’ CATIA V5 design tools in a file-based environment. “During the initial work on this project, we were trying to manage without any kind of product lifecycle management (PLM) solution, but it was incredibly difficult to operate in that way,” said Henriques. “There were a lot of manual processes and files stored locally. Change management and version control was impossible – and so there were a lot of inaccuracies.”

The 3DEXPERIENCE platform, including ENOVIA for project management, would solve these problems. “We knew the platform was the right choice for us,” Henriques said. “We have been working with Dassault Systèmes’ design tools since Akaer’s conception, and we didn’t want that to change. The 3DEXPERIENCE platform would mean we could continue to use the CATIA design tools we were familiar with, but in a single unified environment. ENOVIA would give us a bill of materials, requirements management, and improved changed management.”

Henriques needed to find a way to implement the solution in record time. With that in mind, he set about creating a team to help.

“We had more than 70 people involved,” he said. “Ten from Dassault Systèmes, six from our local implementation partner LWT Systems, and the rest from Akaer, including our ICT team and key users from the administrative team, the legal department, the supply chain team and the engineering team. It was an intense experience.”

But making sure that everyone worked together effectively started off as quite the challenge. “We began the implementation with all parties working from different locations – Dassault Systèmes and LWT Systems were external, and our internal teams were geographically dispersed too,” Henriques said. “After a week, we realized that wasn’t going to work. There were too many grey areas in terms of responsibilities. Some activities were being replicated, whereas others were being missed.”

Working as one team

Recognizing that something needed to change, Henriques found a large office space where everybody from the implementation team could work together in the same location. “I called it my ‘war room,’” Henriques said. “It meant everyone was able to see what each other was doing. We could work closely together and solve problems as a team. This was a total game-changer.”

By putting everyone together in one place, the individuals from the various organizations began to work as one. “You wouldn’t know who was from Dassault Systèmes, who was from LWT and who was from Akaer,” Henriques said. “If we had a problem, it was the team’s problem. We suddenly saw the implementation run at a new speed. In fact, the implementation was completed a week ahead of schedule – in just 53 days.”

And it wasn’t just the implementation that was fast – training happened at pace too. Because the team were already heavy users of CATIA V5, they were familiar with the interface and a lot of the operational aspects of the platform. That meant they didn’t need to start from zero when it came to the training program – they only needed to learn the elements that were unique to the 3DEXPERIENCE platform.

“Initially, LWT’s training program was quite comprehensive – it was a two-and-a-half-week process,” Henriques said. “We were able to cut this down significantly and, in the end, all users were trained in a matter of days.”

To prepare for the platform going live, Henriques made sure a team of people from Dassault Systèmes were on hand to iron out any teething problems. “It turned out we didn’t actually need this support,” Henriques said. “By the first afternoon, we were all using the system. It was strange because there was total silence – everybody was working.”

I called it my ‘war room.’ It meant everyone was able to see what each other was doing. We could work closely together and solve problems as a team. This was a total game-changer.

A modern approach for engineering

Akaer never looked back. “The 3DEXPERIENCE platform has transformed the way we work,” Henriques said. “We now have integration. Everybody speaks the same language. It’s like our war room scenario, but in a virtual environment.”

“We saw the benefit of moving from CATIA V5 to CATIA in the 3DEXPERIENCE platform right away,” adds Mucio Melo, who leads the engineering team at Akaer. “We have greater control over the development of drawings, especially around version control. Previously, we managed versions using an Excel spreadsheet, which was far from ideal – it led to many errors. Now, thanks to ENOVIA on the platform, we have full traceability of our designs.”

Now that everybody works in the same environment, accessing a single source of information, Akaer can make the transition to concurrent engineering – a process where the design and development of products happens simultaneously, rather than consecutively.

“It’s not even a case of reducing cycle times like it was in the past, it’s a case of doing everything simultaneously,” Ferraz said. “That brings huge challenges. You must learn how to think in sequence and work in parallel. That can only be done if we have the tools that put different teams in the same environment so that they can generate information together. Requirements need to be defined from day one.”

Ferraz offers an example: “In the aerospace world, normally the critical design review (CDR) stage precedes the production of parts. We do a design, decide it is mature enough, and then start producing. But what is happening today is we are producing products with complex assemblies and robots. And, actually, the cycle to generate the robot is longer than the cycle for the products. So now we must generate information for the robots’ assembly process before we finish the product design. So, we must invert the order of sequence.”

By engineering products concurrently in the 3DEXPERIENCE platform, Akaer decreased product development time and the time to market, improved productivity and reduced costs too.

Additionally, the first project on the platform progressed without a hitch. “We have been able to complete the first stage of the project for the Brazilian Army – from conception to design and testing – in less than 18 months,” Ferraz said.

This involved meeting over 500 requirements. “Most of those requirements go through multiple disciplines – whether that’s mechanical, electrical, fluids or electronics – and each discipline is managed by a separate team residing in a different location,” Melo said. “The platform was essential to managing this complexity and ensuring all teams could cooperate effectively.”

The project also required Akaer to manage thousands of parts for several different product variants. “Having an accurate bill of materials is essential for this,” Melo said. “As we advance through the next stage of the project, we will have even more variants to manage. The only sensible way to do this is with a platform like the 3DEXPERIENCE platform.”

If you want to work on complex projects, with multidisciplinary teams, you must have integration. It’s simply not possible to work in this complex environment without it. The 3DEXPERIENCE platform provides that integration – it’s invaluable to us.

Thinking for the future

Since its first project, Akaer has worked on three additional projects on the platform. “Adopting the 3DEXPERIENCE platform is proving to be a competitive differentiator for us – having the latest technology is helping us attract new clients,” Ferraz said.

It’s no wonder, then, that the team wouldn’t hesitate to recommend it to similar organizations. “If you want to work on complex projects, with multidisciplinary teams, you must have integration,” Ferraz said. “It’s simply not possible to work in this complex environment without it. The 3DEXPERIENCE platform provides that integration – it’s invaluable to us.”

Silva agrees: “As we look to the future, we want to elevate the way we work,” he said. “Thanks to our partnership with Dassault Systèmes, I am confident we can do this. I look forward to what lies ahead for us.”

As we look to the future, we want to elevate the way we work. Thanks to our partnership with Dassault Systèmes, I am confident we can do this. I look forward to what lies ahead for us.

Discover more about the Engineered to Fly industry solution experience.

Focus on Akaer

Akaer, founded in 1992, is specialized in supplying complete engineering solutions in different areas such as aerospace, defense, energy and automotive. With over 600 highly qualified employees, Akaer is working on the development of strategic projects for Brazil and abroad.

For more information: https://www.akaer.com.br/en

Focus on LWT Sistemas

LWT Systems is a Brazilian company with more than 25 years’ experience taking product development solutions to the automotive, aerospace, industrial equipment and consumer goods markets. It has been working as a partner with Dassault Systèmes for more than 15 years and has experience deploying and supporting all 3DEXPERIENCE tools including CATIA, ENOVIA, DELMIA, 3DVIA and ICEM Surf.

For more information: https://www.lwtsistemas.com.br/