Airthium

Airthium is developing a new generation of high-temperature heat pumps that promise to be clean, efficient and low cost for industrial purposes. The company uses the 3DEXPERIENCE platform’s Digital Equipment Continuity solution on the cloud to bring its product to life as it progresses through its lifecycle.

Making industrial heat carbon free

The industrial processes for making everything from steel and concrete to paper and food account for more than 20% of worldwide carbon emissions. Burning vast quantities of fossil fuels to generate the high temperatures needed for melting, drying, separating, reacting and sterilizing materials emits billions of tons of carbon dioxide into the atmosphere every year. As the race continues to find cost-effective and scalable ways of decarbonizing heat production and reaching global climate targets, companies like Airthium have developed solutions to make renewable energy as cost effective, reliable and flexible as fossil fuels.

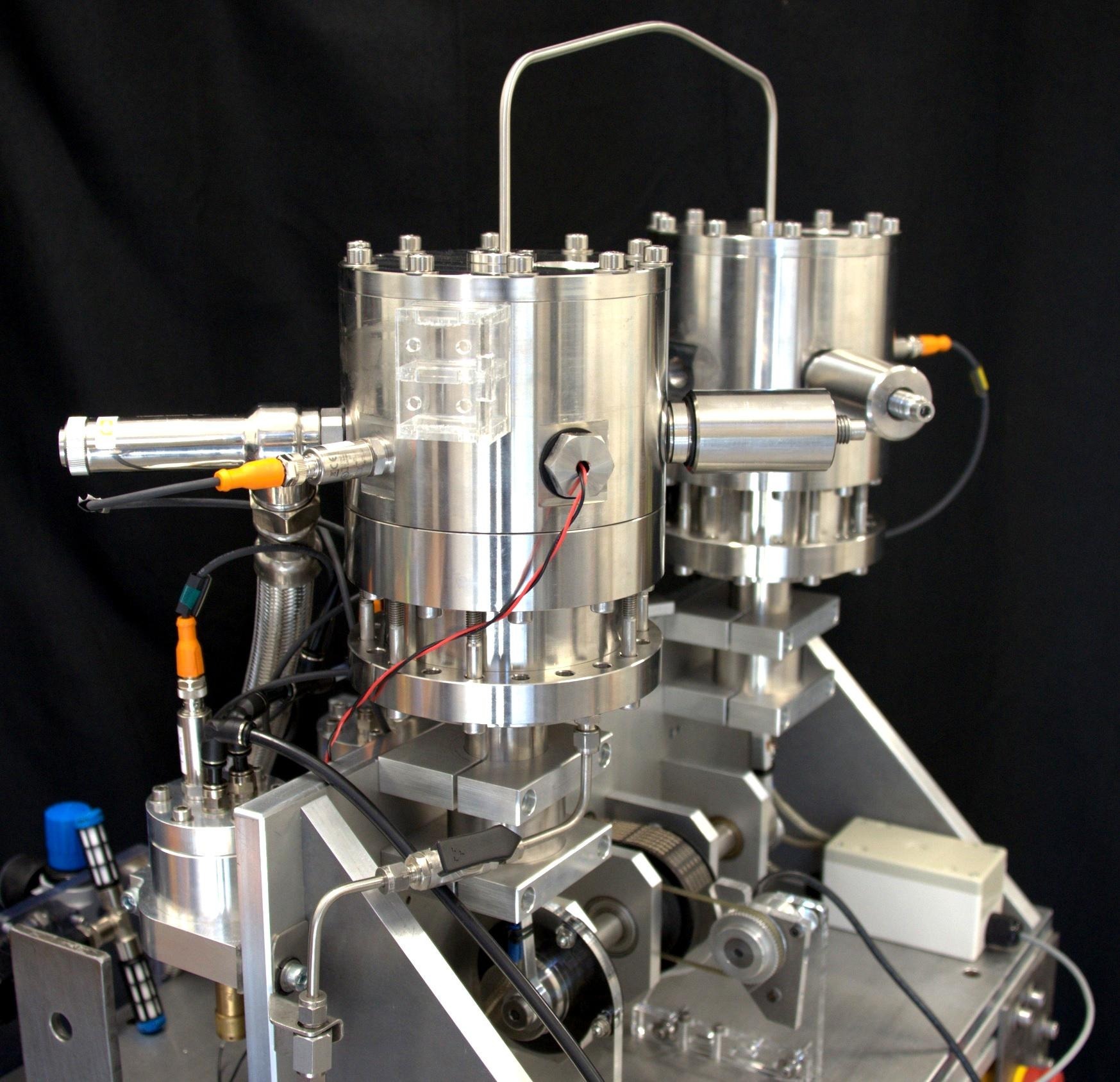

Based in France, the startup is developing a breakthrough heat pump capable of reaching temperatures up to 550°C/1022°F. Suited to the food, paper, automotive and mining industries, Airthium’s heat pump converts electricity to heat, and heat to electricity with record efficiency while producing zero carbon emissions. By replacing gas-fired boilers and dryers, the company expects to remove 3% of the world’s annual carbon emissions.

As Airthium brings its revolutionary technology to market, the company needed a robust platform to manage the entire product development lifecycle and support its designers and engineers to work within a collaborative environment – from anyplace, at any time, on any device.

“When we were looking at options for CAD software, we knew we wanted to also have a robust product data management (PDM) to help engineers move forward with designs without the risk and complexity of managing files by hand,” said Franck Lahaye, COO and cofounder of Airthium. “The 3DEXPERIENCE platform is a great base from which we can grow, and eventually deploy a complete product lifecycle management (PLM) system for the whole company.”

The 3DEXPERIENCE platform is a great base from which we can grow, and eventually deploy a complete product lifecycle management system for the whole company.

Full start up support

Airthium joined the 3DEXPERIENCE for Startups program to gain access to the 3DEXPERIENCE platform on the cloud’s enterprise-level solutions without stretching its budget. It also took advantage of the comprehensive training and support delivered by Dassault Systèmes’ in-house experts.

“Thanks to the startup program, we worked in true collaboration with Dassault Systèmes. They provided a dedicated contact who could help us to implement our processes and answer our questions on how to best use the platform,” Lahaye said.

A cloud implementation made sense for Airthium on many levels, especially as it meant it could be deployed easily. The startup didn’t need to set up its own IT infrastructure, saving on hardware and maintenance costs. At the same time, it gains secure access to its product data from anywhere, at any time, allowing all stakeholders to better collaborate while protecting the company’s intellectual property.

“Having the 3DEXPERIENCE as a cloud service is a benefit because it means we don’t have to have dedicated IT personnel to manage servers and PDM software,” Lahaye added. “Modifications are immediately available to the whole company, without any hassle on our part.”

Centralized design and product data management

Airthium is taking advantage of the powerful design and project management functionalities of the 3DEXPERIENCE platform. The company uses CATIA’s mechanical engineering roles to design all elements of its heat pump. Storing all 3D part models in the 3DEXPERIENCE platform on the cloud and using ENOVIA’s bill of materials and change management capabilities helps to create an end-to-end collaborative change process that clearly communicates the effect of any modifications.

“The PDM capabilities of ENOVIA on the 3DEXPERIENCE platform are very important for us, because they reduce the risk of errors and secure our data management workflows,” Lahaye said.

Airthium has already successfully created a room temperature prototype of its heat pump and will shortly unveil the first 250°C prototype. As the company progresses through the product development lifecycle and brings its engine to market, having a centralized development environment will be key for orchestrating all disciplines and maintaining full traceability and visibility at every stage.

“As we grow, we envision transitioning more of our business roles and tools into the 3DEXPERIENCE platform to further enhance collaboration between our teams,” Lahaye concluded.

Looking to the future, Airthium’s roadmap goes beyond solving carbon-free industrial heat. Once it proves its engine’s reliability and reduces unit costs, the company plans to sell the same engines to renewable energy project developers to power seasonal energy storage systems.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on Airthium

Based in France, Airthium provides solutions for reliable, low-cost, efficient and clean industrial heat supply up to 550°C/1022°F with the help of a first-of-a-kind very high temperature heat pump. The company plans to decarbonize industrial heat between 160 and 500°C, and then electric power generation, using the same breakthrough heat engine.

For more information: https://airthium.com

Focus on XD Innovation

XD Innovation is a Dassault Systèmes partner that strives to help its customers innovate more efficiently by supplying the best-in-class technologies powered by the 3DEXPERIENCE platform. The company provides software, consulting and value-added services covering product development technologies, 3D design, engineering, modeling, simulation, data management, process management, and quality and compliance. XD Innovation takes advantage of a consultative customer engagement strategy and rapid implementation methods to provide superior training and support.

For more information: https://xdinnovation.eu/en