Education Initiatives

Remotely with a Drone-a-thon or on-site with a new 3DEXPERIENCE Education Center, education continued to progress and develop new skills.

Pursuing sustainability in India with drone-a-thon

Drone-a-thon is a virtual hackathon organized by Dassault Systèmes 3DEXPERIENCE Lab and the Drone Federation of India to encourage students and others to design drones using the 3DEXPERIENCE platform. Drone-a-thon is aimed at universities, startups and non-profit organizations, and has four categories: agriculture, city, healthcare and defense/logistics. Participants use the platform to design their projects and carry out simulation and systems engineering work.

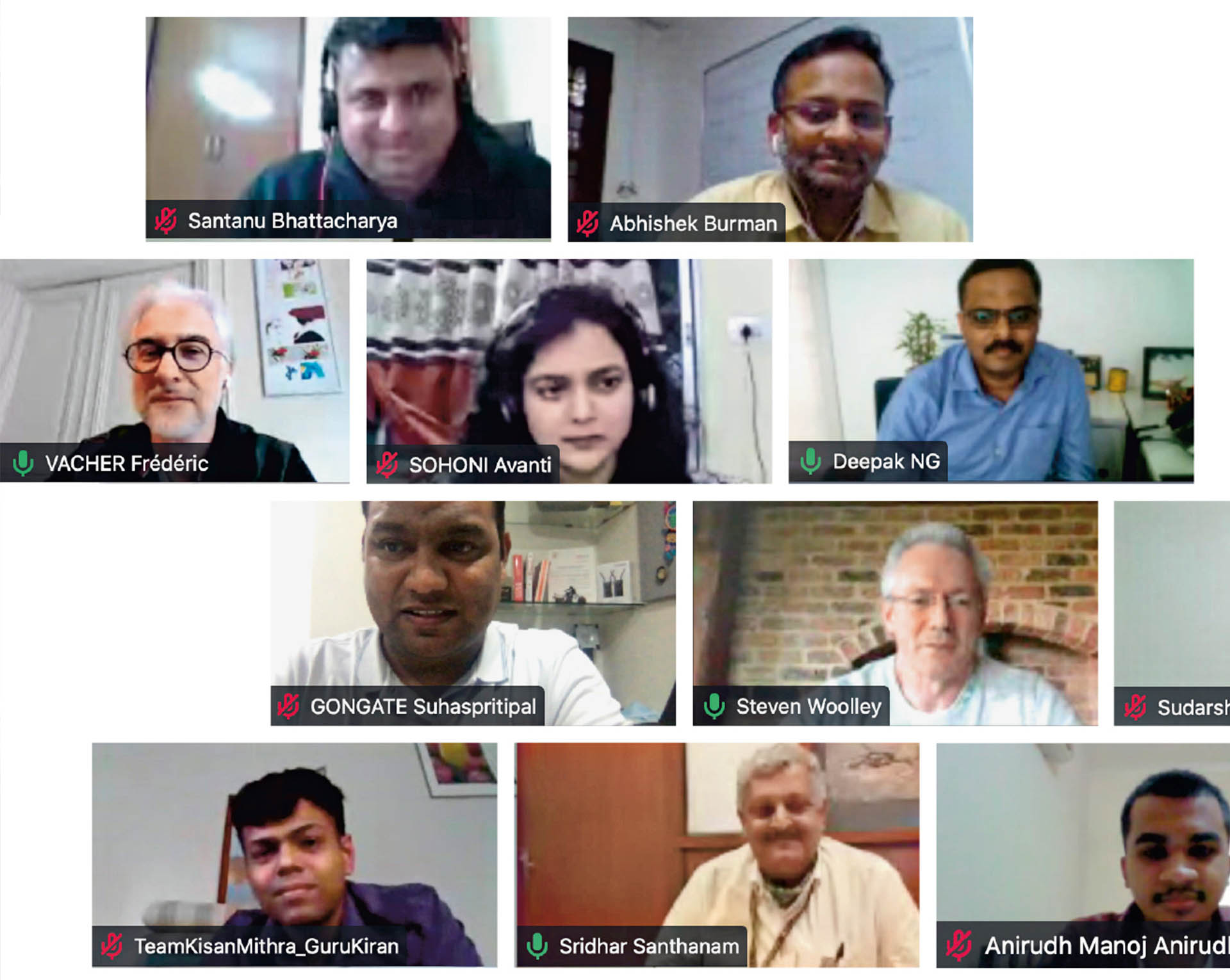

The first phase involved a challenge that narrowed down the field between October 19-31, 2020. In the second phase, selected teams received training in how to use the platform and designed their drones as part of a hackathon from November 9-20, 2020. In the third phase, 10 selected teams presented their drones to Dassault Systèmes employees and an in-house panel, and five were selected through a vote by a community of the platform’s users. In the final phase, the five teams presented their concepts to a panel of industry and academia professionals, and three winners were selected.

The overall winner was Terneagle, a quadcopter drone that can switch to glider mode once it has reached a certain altitude, since its aerodynamic structure is compatible with both types of flight. The second winner, Pegasus, a tilt-rotor VTOL, combines the vertical take-off capability of a helicopter with the cruising speed of an airplane. Finally, Agro-Raptor is a robust drone designed to carry heavy loads.

Speaking the language of innovation at the purdue center

“The language of innovation in the future will be simulation,” said Dr. R. Byron Pipes at the opening of the 3DEXPERIENCE Education Center of Excellence in Advanced Composites. Dr. Pipes, Distinguished Professor of Engineering and Executive Director of the Composites Manufacturing & Simulation Center (CMSC) housed at Purdue University’s Indiana Manufacturing Institute, is a world-renowned specialist in the field of composite materials.

“The knowledge base we’ve created currently resides in books, magazines and academic papers. Eventually, it will reside in simulation tools. This is where the future is going,” he added. The aim of the Center of Excellence is to create a learning environment for research into the manufacturing and performance of advanced composites and the engagement of all levels of students, in order to develop the knowledge required for Industry 4.0.

Dassault Systèmes’ center is located within the Indiana Manufacturing Institute at Purdue Research Park. One of the materials being developed there, a new thermoplastic composite, could help drive development in urban air mobility, drones and aerospace platforms. By giving designers a way of trying out innovative new materials and manufacturing processes virtually, the aim is to speed up the creation of new systems with the students of today and generations to come.