Developing tomorrow’s talent

Bringing together research, teaching, business to create a solid base of knowledge and expertise is a crucial part to be future ready.

Stars in the eyes of young American scientists

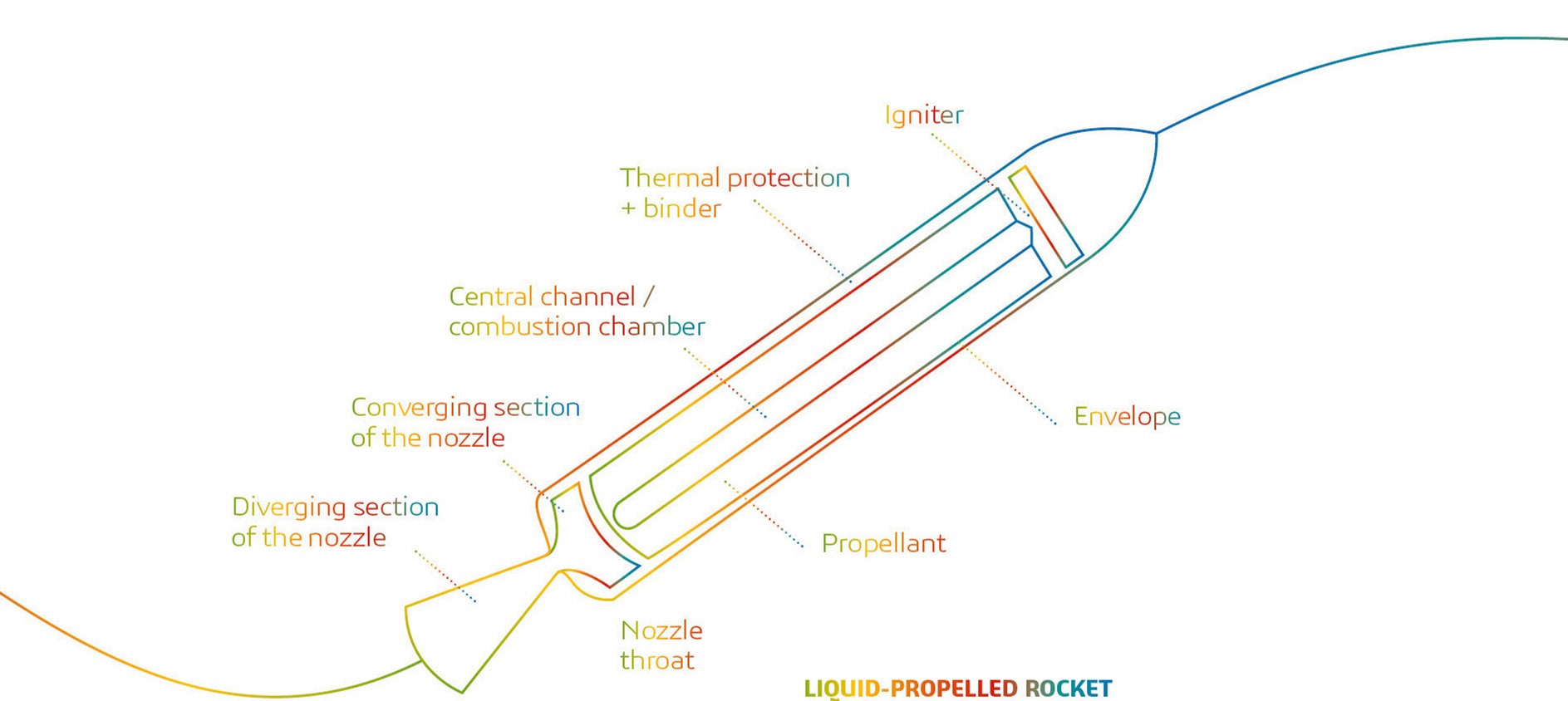

In the United States, a prize of more than $1 million awaits the team of STEM students that wins the Base 11 Space Challenge. The challenge is to design, build and launch a liquid-propelled rocket to an altitude of 100 km (62 miles) by December 30, 2021. The challenge is a real opportunity to showcase STEM (science, technology, engineering and mathematics) skills.

With the aim of fostering talent and generating interest in space-related careers, Space Challenge encourages universities to build up their rocket-related programs, and gives students the chance to learn through access to critical resources and world-renowned experts. The teams taking part in the challenge are gaining practical experience in engineering, prototyping, testing, failure analysis and data management, but also teamwork, collaboration and innovation.

Dassault Systèmes is partnering with Base 11 by providing its 3D design and simulation solutions, and is giving all student team members the chance to gain SOLIDWORKS and CATIA certification free of charge.

A new campus for education and vocational training

Marseille-based engineer Henri Fabre invented the seaplane, which flew for the first time over the Étang de Berre lake in 1910. So it’s fitting that the Henri Fabre education and vocational training campus (“Campus des Métiers et des Qualifications” or CMQ) should be built on the banks of that lake in Marignane, France.

This hub of secondary and higher education and vocational training establishments, supported by employers and an array of public-sector partners, is also the site of a startup incubator and provides advice to local SMEs on the technologies involved in the industry of the future. Dassault Systèmes, by providing solutions from its 3DEXPERIENCE platform, is naturally taking part in the project, alongside Airbus Helicopters – also headquartered in Marignane – and EDF.

The Henri-Fabre TEAM (Technologies & Expertise in Advanced Manufacturing) unit is the industrial part of this economic development project. It oversees a shared innovation hub dedicated to the industries of the future. It is a technology accelerator that, together with its partners, provides manufacturing companies with an array of services, helping them to innovate and diversify, and training employees and students.

Identifying future innovators

Forty graduates took part in the 3DS Hackathon over the weekend of September 8 and 9, 2018 at the University of Western Australia. It was the first hackathon organized by Dassault Systèmes (3DS) in Australia, and its aim was to identify young IT graduates who will be future innovation leaders.

The participants came from a wide variety of backgrounds, but worked in teams, using the 3DEXPERIENCE platform’s generative modeling applications. The students successfully met the challenge of detecting credit-card fraud using machine-learning algorithms. Mechatronic, chemistry and geoscience students impressed the 3DS team with their skills in the Internet of Things (IoT) and machine integration.

Two mechanical engineering groups excelled in their case study, which involved designing and optimizing the configuration of a factory, showing impressive knowledge of manufacturing, intelligent production, robotics, 3D printing and self-driving vehicles.

graduates took part in the 3DS Hackathon over the weekend of September 8-9, 2018 on the campus of the University of Western Australia.

PhD and post-doctoral researchers from Europe, the Middle East, India and China worked in teams on tomodensitometry and MRI images of the femur.

Morocco: pioneering the industry of the future

“The world, industry and industrial tools are changing. Morocco must play a pioneering role by adopting new tools, and ESSTI wants to support that revolution and help the country move towards Industry 4.0.” This is what Chakib Bojji – founder and chairman of the ESSTI engineering science and technology higher education establishment in Rabat – had to say about the inauguration of the 3DS Learning Lab, the first of its kind in North Africa.

Inside the Lab, the customization made possible by the 3DEXPERIENCE platform means that students and teachers have a flexible working environment that can be accessed in the cloud, bringing together all of a project’s essential components. Academic research partnerships with companies and higher education institutions in many countries, including France, India and South Korea, are already in the pipeline.

In addition, ESSTI’s 3DS Learning Lab in Rabat is Africa’s first academic certification center based on Dassault Systèmes tools.

The future of multi-scale modeling

Dassault Systèmes has supported the MultiSim Modelathon, co-funded by the EPSRC (Engineering and Physical Sciences Research Council) and hosted by the Insigneo Institute for in silico Medicine at the University of Sheffield since its inception in 2015. The four-day event brings together the best of theory and practice in the field of multi-scale modeling. In September 2018, the theme of this annual event was the use of digital research in multi-scale modeling of osteoarthritic joints to improve patient outcomes.

Fifteen participants, doctoral and post-doctoral researchers from Europe, the Middle East, India and China worked in teams on CT and MRI images of the femur to better understand the construction of musculoskeletal, finite element, and kinematic models from personalized clinical data.

For Enrico Dall’Ara, a senior lecturer in the Department of Oncology and Metabolism at the University of Sheffield, “The people at this event are the future of multi-scale modeling in the area of Biomechanical Engineering. Bringing them together now, not only helps in sharing knowledge and expertise, but also creating the nextgeneration professionals that will drive our industry and research forward in the future.”