Design for sustainability

To highlight the need and the means to break the modern take-make-waste cycle, Anne Asensio, head of the Dassault Systèmes Design Studio, teamed with London-based, French-born architect Arthur Mamou-Mani, a passionate advocate of renewable architecture. Their goal: to highlight that sustainable design processes begin not with “what do we want to make?” but “what renewable materials should we use to make it?”

UNTIL NOW

Sustainability has been an afterthought in design

FROM NOW ON

Designers are playing a key role in accelerating the circular economy

“Designers always think about materials,” Asensio said. “Unfortunately, designers are rarely invited to participate in a project until after the ‘what is it’ has already been decided, which locks in the material choices and therefore impacts a project’s sustainability. We wanted to make material selection the starting point, not an afterthought.”

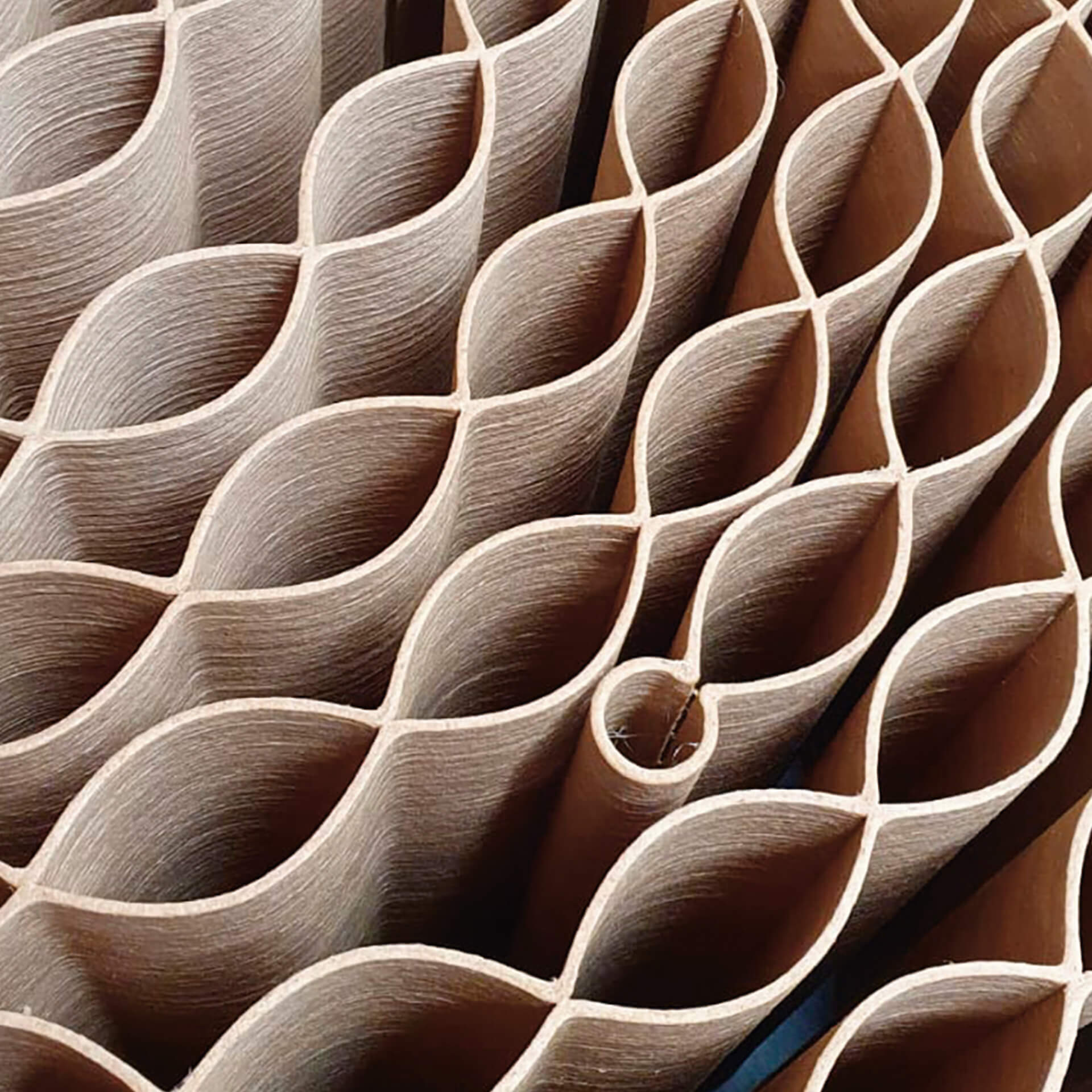

The result? AURORA, a fully renewable art installation of gold-and-crystal modules created from plant-based resin installed at Design Museum of London’s atrium during its 2021 “Waste Age” exhibit.

AURORA embodies Asensio’s regenerative “Design Thinking” approach to truly circular product creation.

Using the 3DEXPERIENCE platform, the globally dispersed Design Studio and Mamou-Mani team members designed the exhibit’s components as virtual twins – scientifically accurate 3D computer models. The teams digitally scanned the museum's atrium, converted it to a virtual twin, and virtually assembled the components. This experience easily allowed for experimentation in arranging the modules and suspension structures, resulting in a design that was beautiful, structurally sound, safe for people to walk beneath and feasible to assemble and disassemble.

The platform’s live-rendering capabilities allowed team members to view the virtual twin from any angle in different lighting, varying the textures and mixing opaque and clear materials. With just a few clicks, they repeatedly tweaked their selections to achieve the desired result.

They then output the modules to 3D printers that used PLA, a plant-based resin that can be crushed, re-melted and reformed into something new or recycled through industrial composting. Importantly, identifying PLA as the project’s main material was the team’s first step. Using the platform’s Sustainable Innovation Intelligence capabilities, an integrated approach to life cycle assessment (LCA), designers understood the environmental impacts of their material and processes before they began to design, allowing them to create a visually stunning exhibit that embodies circularity.

AURORA was conceived as a collection of modular components that could be disassembled to build new products. And so today, its components serve as coffee-table bases, trellises and a host of other products. Unused components were crushed, ready to be re-melted and reformed into new shapes with new purposes.

Design, sciences and industry are converging to conceptualize a new, unified practice in support of a limited planet.