Air quality

The 3DEXPERIENCE platform can be used by engineers to simulate airflows, as well as how a virus could spread in the air.

Air quality: a key issue for the city of tomorrow

Simulating and assessing virus dispersion in a Wuhan hospital

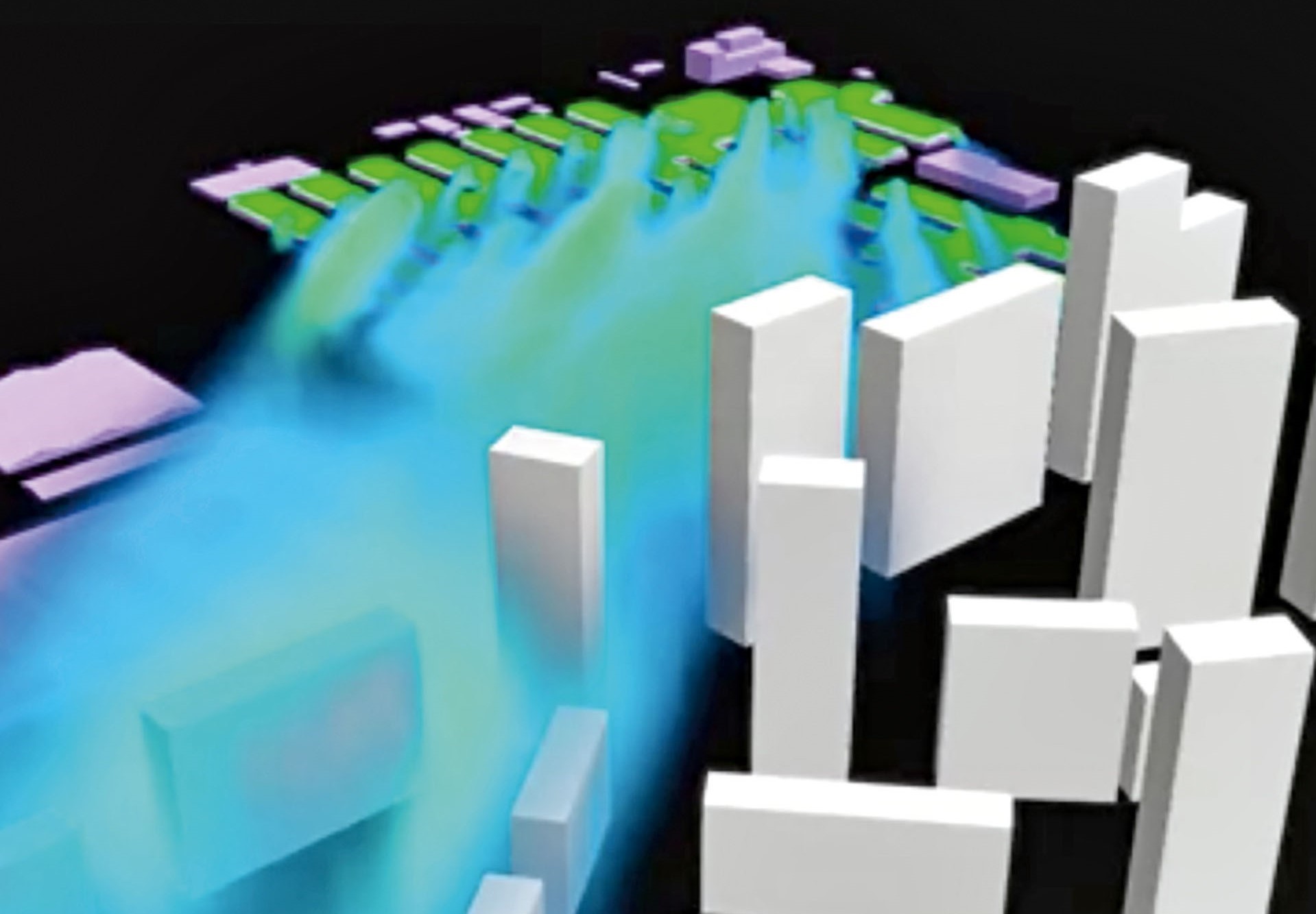

At the start of the COVID-19 pandemic, people all around the world saw many pictures of the Leishenshan modular field hospital in Wuhan, China, which was built in only 14 days. Engineers used the 3DEXPERIENCE platform to simulate how the virus could spread through the hospital’s ventilation system. This helped the designers prevent unplanned risks and avoid infection in neighboring areas, particularly by minimizing cross-infection within the hospital, and preventing any virus repercussions in the surrounding communities.

SIMULIA’s CFD solution, XFlow, was able to simulate internal airflow to ensure optimal removal of contaminated air from negative pressure isolation rooms protecting hospital staff as effectively as possible. XFlow also simulated the impact of aerosol and gas emissions into the external environment near the hospital, helping to determine the design and location of the modular hospital.

Ensuring safety in company canteens

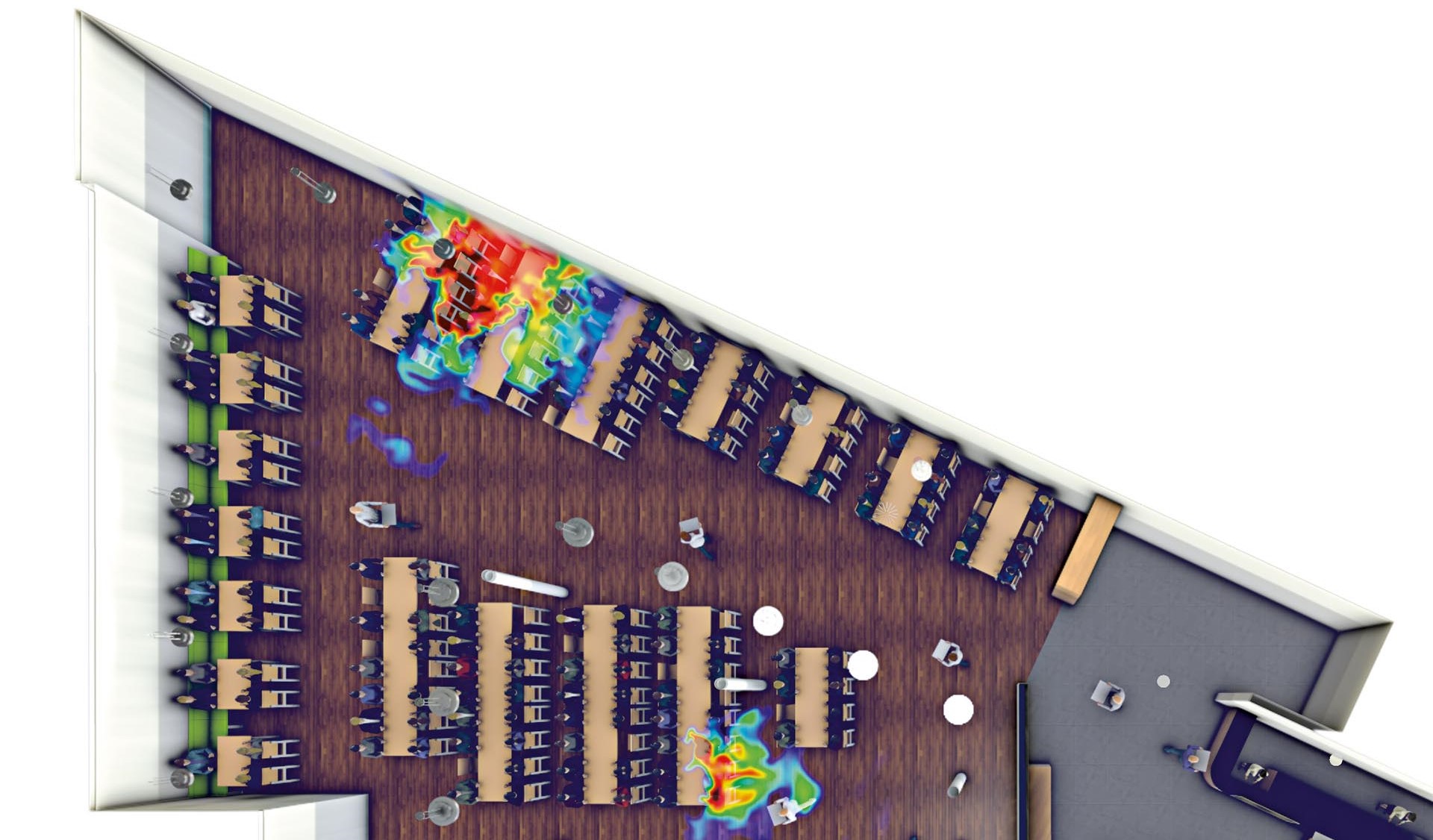

German company GEA is a major player in plant engineering, providing technologies and machines in the food, beverage, and pharmaceutical sectors. For its factory in Oelde, North Rhine-Westphalia, the company contracted Dassault Systèmes’ Engineering Services organization to simulate airflows in the cafeteria, which is used by the site’s 1,900 staff members, with the 3DEXPERIENCE platform.

By using SIMULIA CFD / Fluid solutions, along with key technologies that included PowerFLOW, Dassault Systèmes was able to achieve precise modeling of airflows and the ways in which particles move and are deposited on surfaces in complex environments. The site closed in March 2020 because of the pandemic, and GEA needed a comprehensive risk assessment for the potential re-opening of the cafeteria.

In particular, GEA asked Dassault Systèmes to study the way in which the virus spreads in the air, but also the ways in which it can contaminate surfaces such as plates, trays and tables; the virtual twin showed potential areas where unexpectedly high levels of the virus could accumulate.

GEA used the simulation results to identify and implement an effective strategy to create a safer working environment; it made changes to entrances, exits and seating arrangements, created a separation between the kitchens and the dining room, and adjusted the ventilation system. The simulation results and 3D renderings have the additional advantage of enabling a far more effective communication regarding the protection measures adopted.

Reducing risks of airbone contamination in public areas

The COVID-19 crisis has put the spotlight on how viruses circulate in the air. In order to be able to maintain public areas safely open or to re-open them when economic and social activity resumes, Dassault Systèmes solutions enable simulating scenarios and identifying efficient mitigation measures. This is true for a wide range of venues, including hospitals, administrative buildings and office spaces, cultural and tourism venues, transportation and more.

During the pandemic, Dassault Systèmes initiated collaboration with several French hospitals (AP-HP) to simulate airborne particle flows and the deposit or carriage of pathogens. These projects were essential to confirm the scientific value of simulations deployed around patients, their environment and the risk of contamination within the hospital.

The pooling of medical and field expertise of the AP-HP team, plus the simulations performed by Dassault Systèmes, allowed a new approach for scientific understanding. These projects provided outputs immediately exploitable by the hospitals to confirm or adapt the mitigation actions they were planning to adopt: As an example, the simulations performed enabled Bichat Claude- Bernard AP-HP hospital to reorganize a trauma room by optimizing the orientation of patient beds, understanding surface contamination and adding air filtration systems in the ceilings over COVID-19 patients.

Dassault Systèmes‘ SIMULIA teams also assessed, with “La Pitié-Salpêtrière” hospital in Paris, the adequacy of reorganizing a post-intervention monitoring room, which could be occupied to modifications. Together, they ran different scenarios inside this room, which could be occupied by a dozen infected or healthy patients, to define the best arrangements for both medical staff and patients’ security.

“We must continue to take a proactive approach in helping minimize the impact of this virus on our fellow citizens and healthcare systems,” said Claire Biot, Vice President, Life Sciences Industry, Dassault Systèmes. “Simulation can be used to improve safety in hospitals, nursing homes and specialized clinics, as well as to optimize the floor plans of hospitals that have not yet been built. This collaboration is all part of our mission to harmonize product, nature and life, and make the world a better, safer, healthier place.”

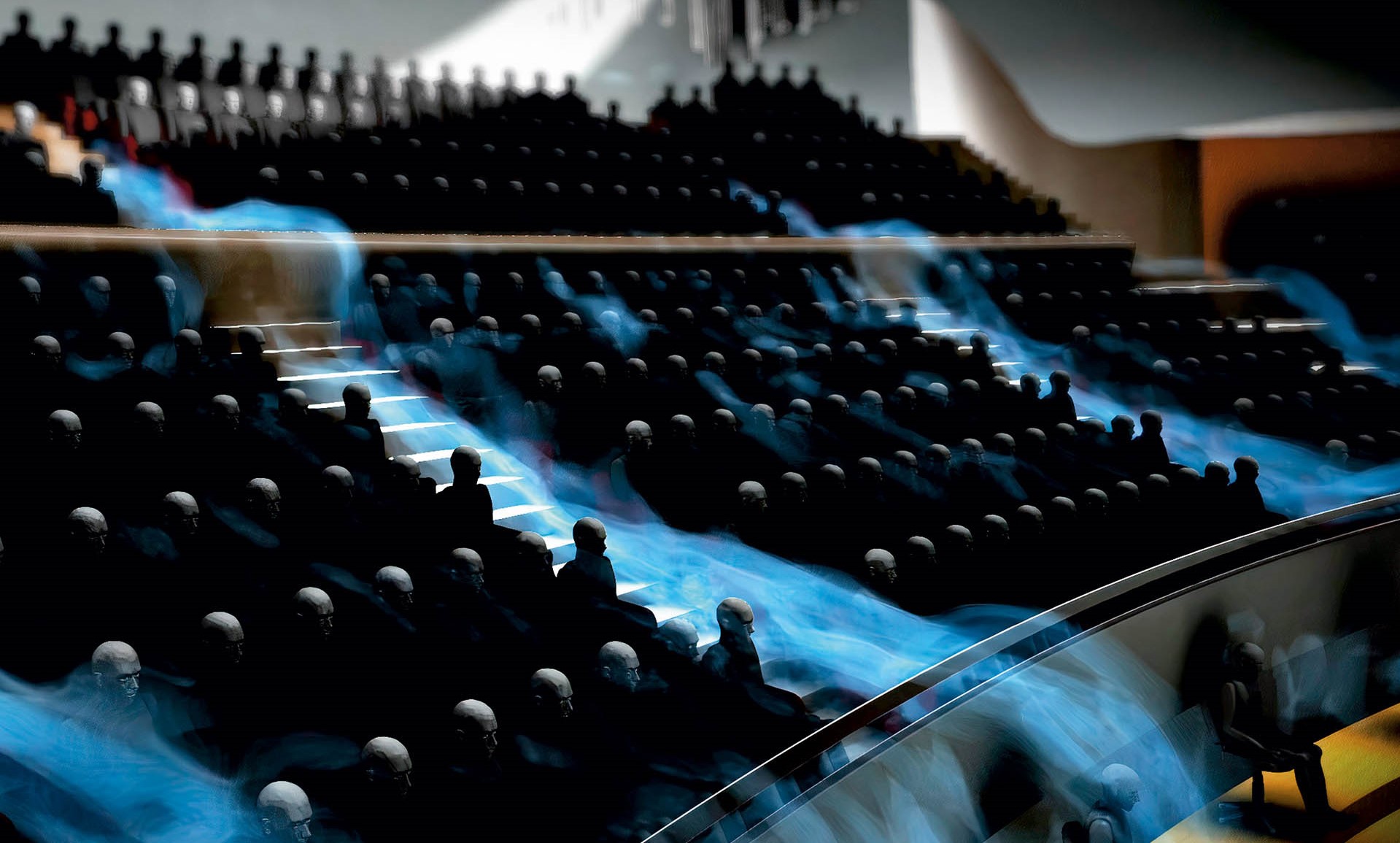

Thanks to the expertise developed with hospitals, Dassault Systèmes also helped La Philharmonie de Paris, the French capital city’s philharmonic landmark, prepare to safely reopen its largest concert hall. With a capacity of 2,400 seats, the Grande Salle Pierre Boulez features an enveloping configuration that immerses the concert hall audience in the music, and a unique ventilation system in each seat that quietly introduces fresh air and regulates its direction and speed.

Equipped with data provided by the Philharmonie de Paris, Dassault Systèmes created a model of the concert hall at full capacity in 3D, and simulated the airflow from the uppermost balconies to the orchestra floor, in order to assess the impacts of mask wearing and airflows on virus-particle dispersion. Simulation was used to experience and understand how air circulates within the space, evaluate the effectiveness of the Philharmonie de Paris‘ preventive measures, and identify new ones if necessary.

“Safety is non-negotiable, for our public, artists and staff. This is why we decided to partner with Dassault Systèmes. Thanks to their cutting-edge simulation technology, we are prepared to reopen our concert hall in the best possible conditions.” — Laurent Bayle, Managing Director, La Philharmonie de Paris.

“Our collaboration with the Philharmonie de Paris is part of our ongoing efforts to help organizations simulate, visualize and analyze existing conditions, evaluate the impact of ‘what-if’ scenarios, and identify solutions to open and operate safely,” said Florence Verzelen, Executive Vice President, Industry, Marketing and Sustainability, Dassault Systèmes. “There are no rehearsals in life. As the real world struggles to emerge from pandemic-related lockdowns, the virtual world allows for experimentation to reveal these unknowns”