The Model-Based Approach for Battery Innovation and Manufacturing

Secure an advantage to deliver best-in-class batteries with the power of virtual twins.

Rechargeable batteries play a pivotal role in securing energy continuity as we move away from fossil fuels. With batteries empowering the transformation of many industries, battery manufacturers face growing pressure to increase battery production capacity and deliver high-performance batteries to market quicker.

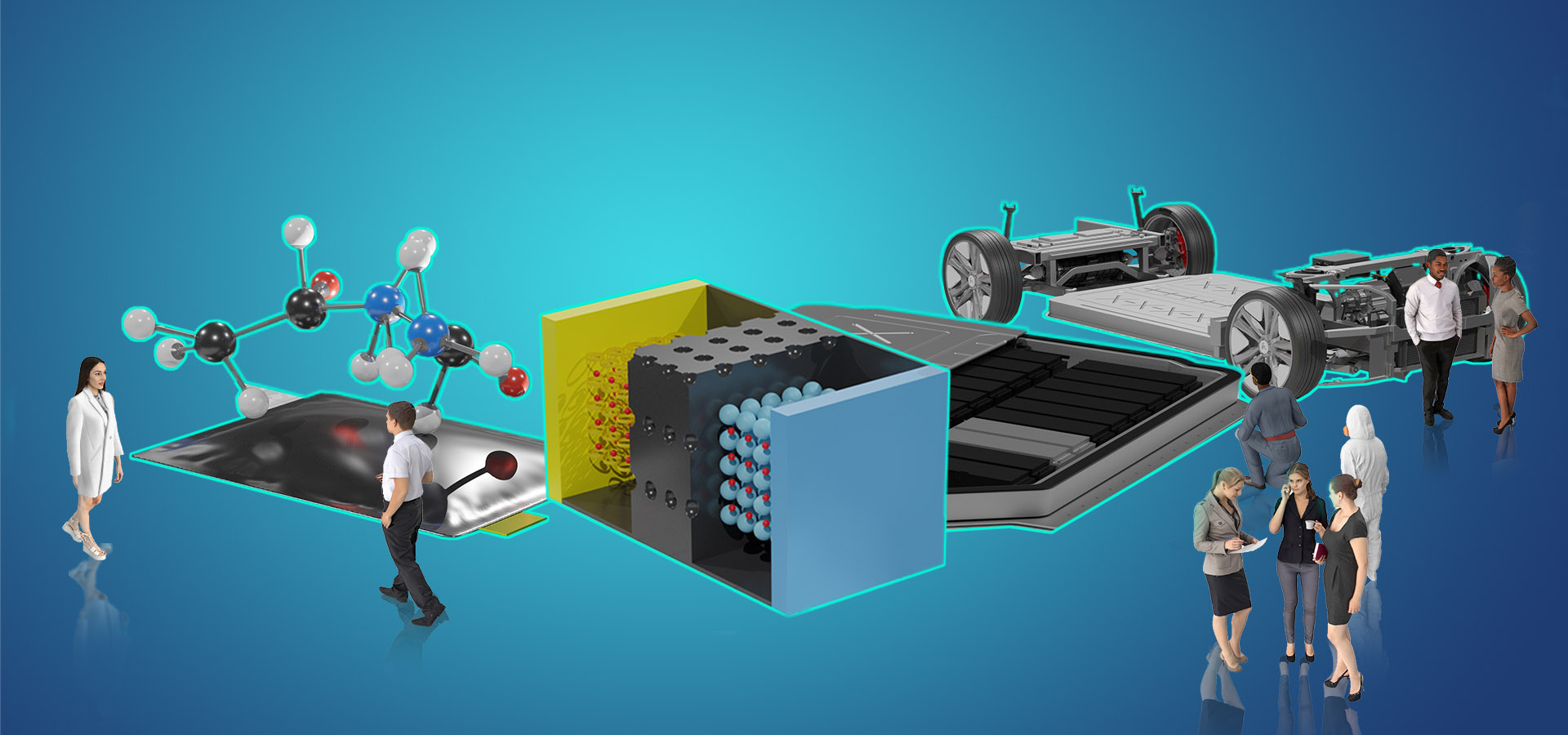

By leveraging a model-based approach, today’s battery innovation leaders have increased their lab productivity by 40% and reduced shop-floor planning cycles by 20%. Are you able to keep up and maintain your competitive edge in a global battery market forecasted to be worth $360 billion by 2030? Discover the strategy to accelerate and de-risk battery innovation with modeling and simulation for your products, processes and business across all battery domains:

Innovate at Speed and at Scale

In a dynamic, complex and fast-growing marketplace, the race is on to scale up and develop next generation battery materials and technology. How can virtual twins help you discover what is the next battery technology?

“Battery behaviors do not remain static. To innovate at speed and at scale, you must be able to test and improve real world battery phenomena throughout its lifecycle. Virtual twins provide us with accurate real-life battery behaviors and properties, enabling us to improve energy density, charging speed, lifetime performance and the safety of battery-powered systems,” says Rudy Pastuzak, Battery Industry Solution Experience Director at Dassault Systèmes.

Fast-track Battery Innovation and Manufacturing With Virtual Twins

- 30% fewer physical prototypes

- 30% shorter manufacturing cycle time

- 10% faster new product introduction

Our factsheet contains the full details of KPI improvements to help you stay ahead in battery R&D, engineering and manufacturing.

Regulators in the United States and Europe are identifying frameworks that include virtual twin models and simulation as sources of evidence in new product approvals. It’s not just about modeling and simulating the product, but also validating processes from start to finish in a single environment for digital continuity.

Get Battery Innovation Right the First Time

Battery materials design, battery cell engineering, battery manufacturing and other disciplines involve a highly complex ecosystem, spanning a wide scope of interconnected operations and processes. Poor visibility and inefficiencies caused by the lack of cross-functional collaboration can significantly impact your time to market.

According to Mellier, “You need to be armed with the right data at every stage because real-time access to information is no longer optional. That’s why Battery Digital Passport initiatives aim to establish traceability into the entire battery lifecycle. Virtually testing and validating a product or process will drive agility and significantly accelerate quality management processes in battery innovation."

Seamless End-to-End Collaboration

At the heart of the model-based approach is Dassault Systèmes’ 3DEXPERIENCE® platform, which unifies each function of a battery’s lifecycle from ideation to system integration. Serving as the backbone that connects all stakeholders in the ecosystem, the platform offers more effective stakeholder engagement and supports optimal task execution across all battery domains.

Collaboration on the integrated 3DEXPERIENCE platform equals faster and more efficient processes and operations. The stories below highlight how the platform offers seamless collaboration, modeling and simulation in one virtual environment:

Verkor is leveraging virtual twin technology on the 3DEXPERIENCE platform to speed up the development of next-generation lithium-ion batteries and the first giga factory that will produce them.

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives