Master the Future of High-Tech Manufacturing with Symbiotic Value Networks

Leveraging Virtual Twins to Synchronize Manufacturing and Engineering to Accelerate Delivering Competitive Connected Devices and Systems.

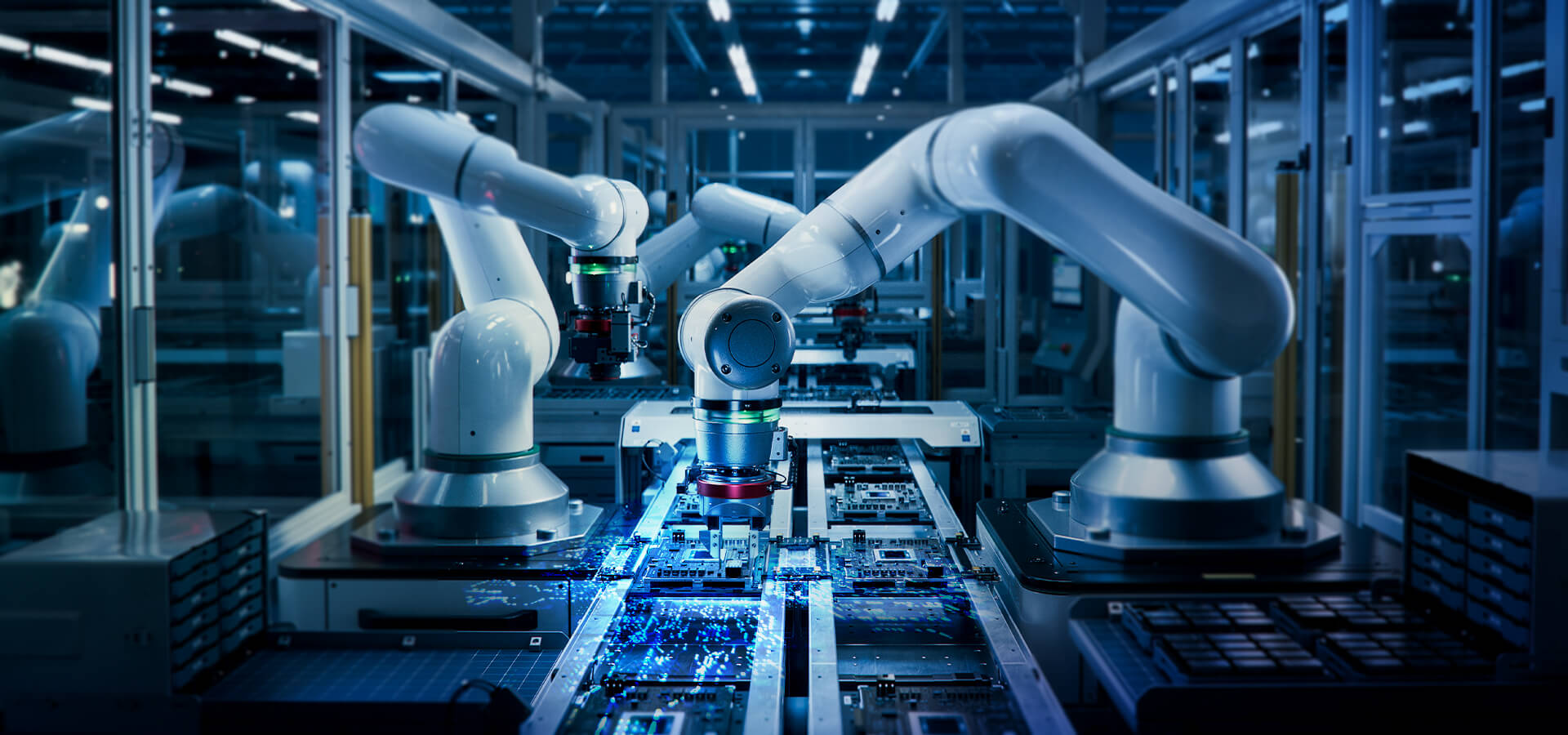

In today’s rapidly evolving high-tech industry, success depends on more than just innovative products—it requires a seamless integration of engineering, planning, and manufacturing processes to adapt and thrive in a competitive market. Leading companies are embracing symbiotic innovation value networks, where manufacturing and engineering work hand-in-hand, enabled by advanced digital tools like the virtual twin.

Webinar "Symbiotic Value Networks in Action"

Leverage the digital, model-based synchronization of manufacturing and engineering.

A virtual twin is more than a digital replica of a product; it dynamically mirrors the entire production process, allowing manufacturers to simulate and optimize operations before anything physical is built, as well as adapting and growing as manufacturing operations data is fed back to the twin. This approach not only cuts time-to-market by up to 30%, but also enhances quality, reduces costs, and boosts productivity while minimizing capital investments.

For example, Panasonic Connect used its Virtual Twin to streamline its factory operations, reducing bottlenecks and improving overall throughput. By leveraging the Virtual Twin, they were able to foresee and fix potential issues, delivering high-quality products faster and more efficiently.

Panasonic Connect

Streamlining factory operations with Virtual Twins.

What makes this strategy transformative is its capacity to unify and enhance every stage of manufacturing—from the factory planning to full-scale production. By providing real-time feedback and synchronizing processes, companies can react to disruptions swiftly, optimize resources effectively, and train their workforce using virtual and augmented reality for first-time-right execution.

Virtual Twins enable a closed-loop system that creates a powerful feedback cycle, ensuring continuous improvement across the entire ecosystem. With the digital synchronization encompassing engineering and manufacturing, companies can propel their strategies for sustainable competitive advantage in delivering connected high-tech devices and systems.

Integrating data intelligence, machine learning and advanced process simulation enables high-tech companies and their value chains to quickly optimize operations continuously, to ramp-up new workers in the factories quicker and keep permanently agile and resilient.

Watch our 17 min webinar to discover how the 3DEXPERIENCE platform empowers your teams and ecosystems to successfully deliver your high-tech innovation.

Leveraging Virtual Twins in Manufacturing High-Tech Devices and Systems

Watch our free webinar showing how high-tech companies can empower a symbiotically organized value network across product engineering, process planning, scheduling and operations.

Discover More

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives.