It goes without saying that nobody likes earthquakes. The ground shakes, structures topple, and people get hurt. Interestingly enough, a growing number of these events are caused by, or at least related to, human activities. The construction of buildings on soft, unstable land or near known geological faults are two examples, as are induced earthquakes that arise due to the extraction of oil and gas.

Engineering for the worst

Fortunately, humans are able to reduce and, in some cases, eliminate the negative effects of earthquakes, whatever their cause. By isolating a building from the surrounding earth, reinforcing the walls and foundation and then placing the entire structure atop a complex series of springs or sliders, it is possible to keep our office buildings, apartment complexes, and similar living spaces safe from all but the worst of Planet Earth’s unexpected moves.

Mark Slotboom spends his days doing just that. A structural engineer in the Netherlands, he and his coworkers have become specialists in designing innovative ways to protect buildings, new and existing, in the event of an earthquake. Their employer is Zonneveld ingenieurs, a Rotterdam engineering firm with 35 years of experience designing load-bearing steel and concrete structures for high-rise and civil engineering projects around the world.

Recent projects include the redevelopment of the Pecci Museum for Contemporary Art in Prato, Italy, the Main Press Center for the Olympic Games in Athens, and the Hammersmith offices in London. It is in large part due to complex engineering projects like these that Slotboom and others at Zonneveld first began using Abaqus Unified Finite Element Analysis (FEA) software from SIMULIA, the Dassault Systèmes brand for realistic simulation.

It’s clear that there is a world-wide need for their earthquake expertise, yet Slotboom’s efforts have become increasingly necessary in his own country. Though not prone to geologically-caused earthquakes, in recent years Holland and its inhabitants have quite literally been feeling the effects of oil and gas extraction from the massive Groningen gas field near Slochteren, which leads to geologic stress redistribution and fault slippage—so much so that the government has given leading oil producers four years to cease their sourcing activities.

On shaky ground

Adding insult to injury, much of the Netherlands sits on low-lying marshlands rich in peat and clay, making it especially susceptible to the soil liquefaction common during these self-induced seismic events; whereas a medium magnitude five earthquake in Los Angeles or Kashmir might not make the World News, it can be devastating to Holland. What’s more, with no history of major storms or earthquakes, the Dutch construction industry had become accustomed to designing slender buildings with a simple stacking style, slender walls, concrete floors—and a minimum amount of stability components because gravity was considered to be the main load.

“The Richter scale is somewhat irrelevant in our country,” says Slotboom. “An earthquake in Japan, for example, could originate from a tectonic event many kilometers below the surface, whereas the ones here are relatively shallow, just a kilometer or three deep. Considering the relatively soft soils in this area, these lower-amplitude earthquakes can still be quite destructive to our buildings and other infrastructure.”

Although the oil and gas industry-related quakes are a fairly new phenomenon in the Netherlands, Zonneveld ingenieurs’ efforts at damage mitigation are not. In fact, the company had just completed two earthquake-related engineering projects in Italy and Greece when management decided to upgrade its FEA capabilities with Abaqus, and soon began putting it to good use on their own, now more unstable, land in Rotterdam.

The complexity of the way that Zonneveld ingenieurs are challenging Abaqus is really pushing the limits. We see very interesting support questions coming from them related to special cases in the construction industry. Now, we all know the typical issues in automotive and aerospace - but Zonneveld is simulating earthquakes with totally different structures, so we are pushing the boundaries of the software together.

Designing a quieter, safer living space

That was five years ago. Since then, Abaqus has become the hub around which many of Slotboom and his colleagues’ structural analysis and modeling activities revolve. One recent example of this is a five-story concrete building project that Zonneveld was asked to make earthquake-resistant—the “Merckt” in Groningen, which contains 18 luxury apartments above a ground floor bar/nightclub and restaurant.

The earthquake engineers faced several challenges. Because the Merckt was to be mixed use and located within the center of Groningen (population 200,000), it was important to keep the upper floor residents isolated from the sounds of the ground floor as well as the surrounding city. And of course there were the capital city’s water-saturated soils to contend with, along with the potential for human-induced seismic events.

“We had many decisions to make,” explains Slotboom. “The noise regulations in the Netherlands are strict, which in an apartment building generally means using heavy, concrete walls. But concrete walls are quite stiff, an attribute that creates greater lateral forces during an earthquake than a ‘flexible’ wall made of steel girders. We also had to analyze the soil chemistry, the proposed structure and how it would react to an earthquake, the building codes...there was a lot to think about.” In this case the issue of noise plus earthquake design created the option to combine the separate solutions into one: dampers for both could be placed at common points, and the CDM rubbers that provided acoustic damping were also beneficial for offsetting earthquake forces.

A number of methods exist for making buildings earthquake-resistant. The conventional methods are to make the building structure just strong enough to withstand the earthquake forces or to make the structure ductile enough to overcome the displacements caused by the earthquake motions. More sophisticated options are huge damping mechanisms that sit atop or within the structure and move opposite the earthquake’s force, canceling its energy. Massive springs may be placed beneath the building, slowing its movements in a manner similar to the shock absorbers used in motor vehicles. Or engineers may choose “base isolation” to isolate the building from its surroundings by placing it on bi-directional gimbals, a technology invented centuries ago by the builders of seagoing vessels.

Mitigating the shake

Though they employed a far more high-tech solution than the one used by ancient mariners, this latter method is the direction that Zonneveld ingenieurs took with the Merckt. Together with 4RealSim, a Dassault Systèmes’ value-added reseller for Belgium, the Netherlands, and Luxembourg and FEA engineering services company, the team began by modeling the chemical and physical properties of the soil underneath the proposed structure in Abaqus.

“We started with some localized runs using soil columns that we’d built directly in Abaqus, then applied earthquake signals located roughly 30 meters below the surface,” Slotboom says. “This helped us simulate the ground level response to acceleration levels, soil-structure interaction, and things of that nature, ultimately leading us to the conclusion that we needed a much thicker foundation and basement walls rather than the concrete pilings typically found in large buildings like this.”

With the initial foundation design in hand, Slotboom, Bouwman, and other members of the Zonneveld team collaborated with a local structural consultant, the architect, the contractor and even an acoustic consultant. Relying on previous earthquake engineering experience, Zonneveld determined that the “base isolation” method would be most appropriate for the size and shape of the structure, then set about replicating that environment with simulation.

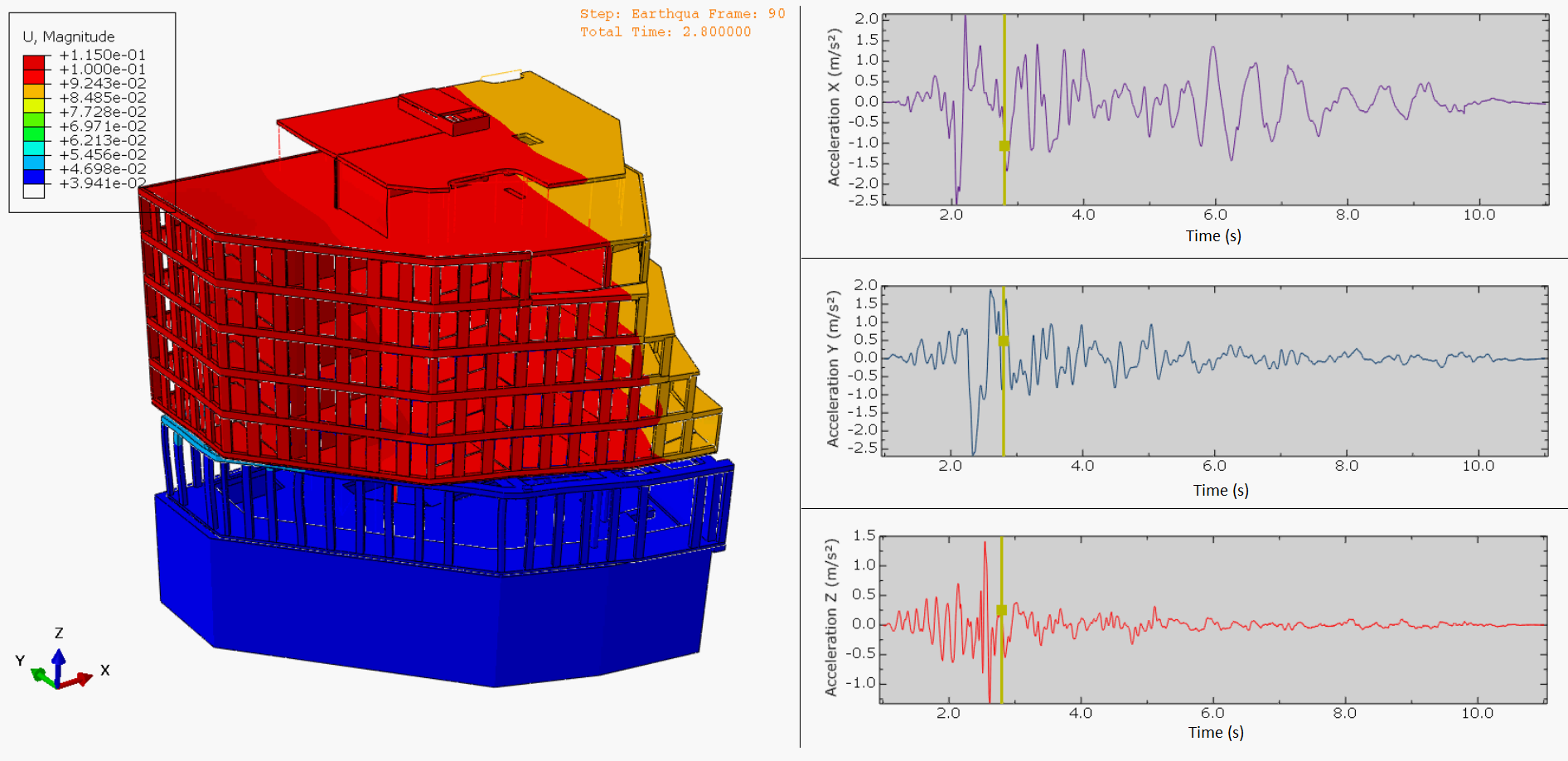

Their approach used the gimbal devices mentioned earlier; these Teflon-lined, “double curved sliders” sit between the ground and first floors, and permit the building above to move in the X and Y axes (back-and-forth or side-to-side). To meet the requirements for noise reduction, the team placed acoustic isolators known as CDM devices (think of them as stiff rubber donuts) atop each of the 30 sliders. Not only do these dampen sound, they also provide some measure of vertical force abatement. With everything modeled in Abaqus, the engineers proceeded to give their virtual world a shake.

Acoustics and seismics work together

The earthquake simulation went far beyond the nudge you might give to a coffee table supporting a house of cards. Zonneveld applied seven “normative signals” based on actual earthquake records, each with distinct frequency, amplitude, and directional seismic forces but scaled to the plot of virtual land sitting under the Merckt. The result was a three-dimensional test of what might happen someday, and how various iterations of the Merckt would respond if it did.

“We had to find a combined solution, one that addressed the acoustic requirements as well as the forces that are present in an earthquake, and the base isolation method went a long way towards addressing this,” says Slotboom. “The CDMs helped reduce the vertical earthquake signal along with the noise of the surrounding environment, but most of the forces during an earthquake are in the horizontal plane. It’s here that the double curved sliders showed the most benefit. Because they are self-centering, the building can come back to the neutral plane once the movement stops.”

Abaqus helped the team determine the correct size and location for each slider, spreading the loads and forces in the most effective manner and ultimately reducing investment costs. The software also illustrated the need for additional design modifications; based on the simulation results, Slotboom and his colleagues saw that they should beef up various beams and other parts of the superstructure in strategic locations to maximize its earthquake resilience.

Digging deep to provide solutions

The Merckt is still under construction, but thanks in large part to Abaqus, Slotboom is confident in the design outcome. “We’re not a big company, but we do like to tackle the more complex projects,” he says. “Abaqus makes us more efficient, gives us more design options, and when we need to dig into a difficult engineering problem, we’re able to do that. This in turn means we can offer greater value to our clients.”

Partner Vincent Bouwman agrees. “Zonneveld ingenieurs is performing a valuable service in the construction industry with realistic studies based on Abaqus that assess and improve the safety of various types of buildings in the Groningen region and

elsewhere,” he says. “We at 4RealSim are happy to support their efforts with in-depth finite-element knowledge, support, training and engineering services.”