Unitsky String Technologies

Unitsky String Technologies, Inc. uses Dassault Systèmes’ 3DEXPERIENCE platform to foster multi-disciplinary collaboration around a single platform to design its transportation networks.

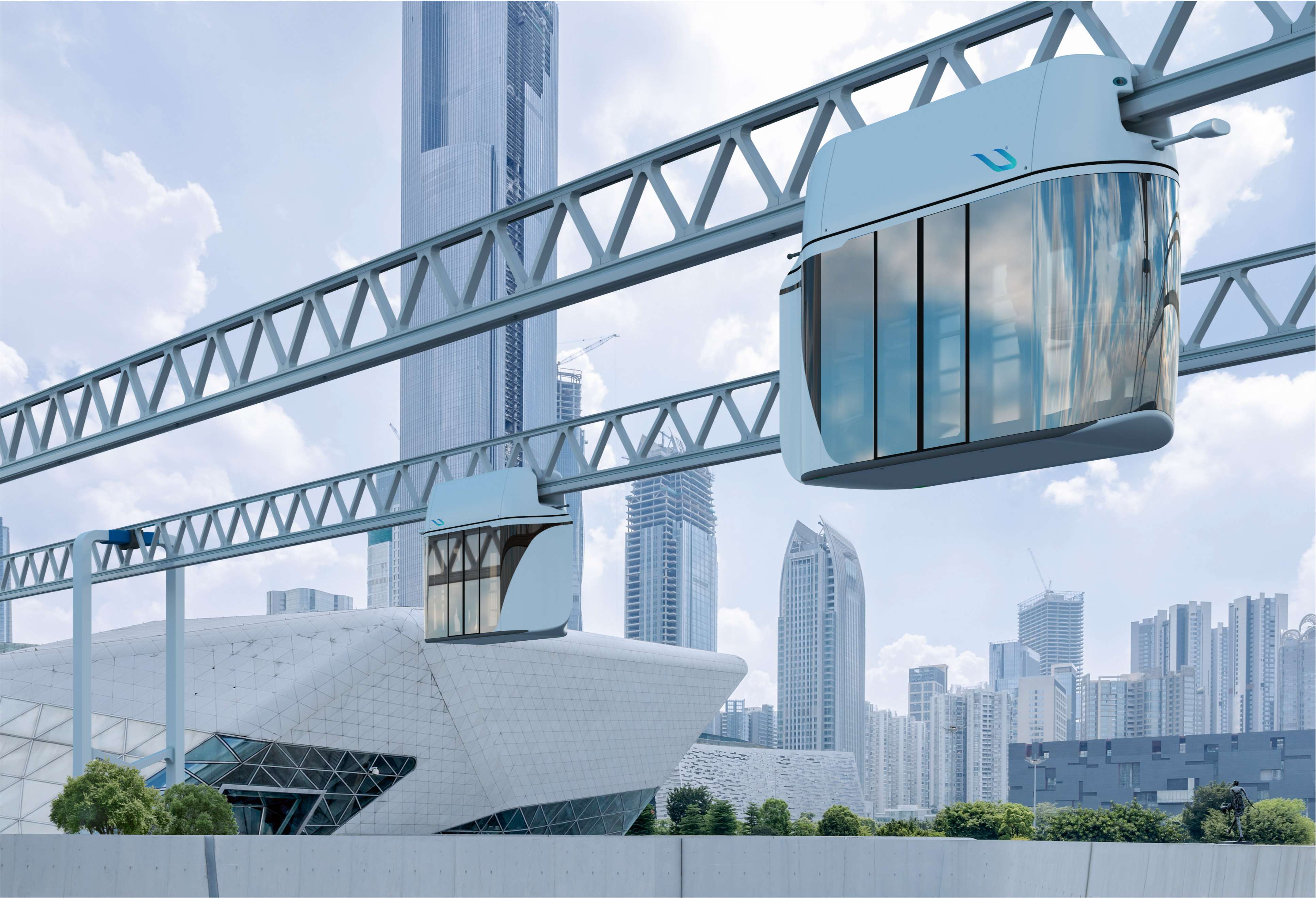

Redefining urban mobility

Anatoli Yunitski, a Belarusian engineer and inventor, wanted to offer citizens in urban and rural regions a new user experience through an approach to mobility that fit in with their lifestyles and that reduced man’s carbon footprint. “In my early years, I was fascinated by space transportation but I realized that we should first optimize our planet’s infrastructure and transportation challenges,” Anatoli Yunitski, founder, president and general designer of Unitsky String Technologies, Inc. said. He founded Unitsky String Technologies, Inc. in 2014 to design and build elevated light rail transportation systems using pre-stressed rails and cables for high-speed urban, rural and freight transport.

“Three billion tons of fuel is burned in car engines alone causing environmental problems, greenhouse gases, and ozone layer depletion,” Yunitski said. “This, along with human safety factors, population growth and an increasing number of private cars, are why we are proposing a new paradigm by creating an ideal means of transportation that does not have any of the above-mentioned downsides. If we take a city like Paris, our string (prestressed rails with prestressed cables) transportation network would cut travel time threefold, which means a person would spend three times less time commuting,” he said. “To bring our systems to life, we use digital technology to help us innovate and cost-effectively manage our projects.”

To design our systems, we use technology to help us innovate and cost-effectively manage our projects. The 3DEXPERIENCE platform enables us to develop a complex transportation network that involves diverse disciplines.

Technology as a means to achieve a dream

The Unitsky transportation system is very complex and comprises a number of systems and subsystems. In the past, Unitsky String Technologies, Inc. had different software for design, engineering and construction of its systems that were not integrated. As a result, data sharing was virtually impossible and development processes were not aligned. To bring all activities into a common environment, Unitsky String Technologies, Inc. adopted Dassault Systèmes’ 3DEXPERIENCE® platform to help the company deal with the complexities inherent with its multi-disciplinary transportation systems. “The 3DEXPERIENCE platform enables us to develop our complex transportation network,” Yunitski said. “We need to attend to the smallest detail and allow our engineers to track the lifecycle of each project through to operation and decommissioning, and be able to find out how and when each part was manufactured. The 3DEXPERIENCE platform is the only solution that makes it possible to implement this type of approach.”

IGA Technologies, a local Dassault Systèmes business partner, deployed the platform at Unitsky String Technologies, Inc. and trained more than 100 users over two months. “They act as methodologists and developers, fine-tuning various aspects of the solution to our needs,” Alexey Voylenko, director of organization development at Unitsky String Technologies, Inc. said. “We have a solid and constructive partnership that is aimed at accomplishing common goals.”

Thanks to the fact that all disciplines share a common platform, all specialists while working on a product, are able to observe the work of colleagues in an adjacent area.

Reducing complexity with a single information source

What makes Unitsky's product development unique is the fact that its entire process involves numerous disciplines, including those that rarely interface. “This includes, for example, mechanical engineering and manufacturing of track structures, which are also both tied to construction,” Voylenko explained. “More than 200 people use the platform in different disciplines like design, hydraulics, pneumatics, chassis, air conditioning, bodies, electrical, electronics and more. We have to integrate many information streams within a single system and connect different developers who normally do not interact with one another. By improving collaboration, we make faster and more informed decisions.”

“Digitally laying out the entire transportation network, rolling stock, route infrastructure and control system in one environment is a big plus,” Voylenko said. “It’s not all that simple to integrate dimension tolerances for mechanical engineering and those typically related to construction. It’s what makes manufacturing and construction of an integrated transportation network so complex,” he said. “3DEXPERIENCE enables all involved specialists to seamlessly mix different engineering standards and visions.”

Unitsky String Technologies, Inc. uses CATIA Systems Engineering to eliminate conflicts as well as errors in the way various components of the transportation system interface. “Thanks to the fact that all disciplines share a common platform, all specialists while working on a product, are able to observe the work of colleagues in an adjacent area. They can assess the work, see how they interface, and promptly work on their own area in accordance with these constraints,” Voylenko said.

“Mechanical engineers who design the track structure are able to see how their work interacts with construction facilities. They track potential conflicts and communicate with one another using chat features and web technologies. We also are now able to engage with other non-engineering specialists in our financial or logistics departments for example, thanks to a common collaborative platform. 3DEXPERIENCE provides a browser version of a product that does not consume much computational power and which is ideal for managers who are more interested in overseeing project KPIs than doing actual design work,” added Victor Garakh, head of the design bureau at Unitsky String Technologies, Inc.. “On the other hand, if you need to perform computations or do modeling work, the platform’s flexibility allows this. Different roles can personalize the system to their needs.”

Digital simulation plays a major role in defining the right production approach. “We run complex calculations with the 3DEXPERIENCE platform’s simulation capabilities and manage our manufacturing operations with DELMIA by virtually testing our production set-up before physical implementation. In doing so, we can identify the best approach to producing our products in the early stages of development. And if there are any design changes, manufacturing information is automatically updated thanks to the link between design and manufacturing data in the 3DEXPERIENCE platform. This considerably improves manufacturing efficiency,” Voylenko added.

The 3DEXPERIENCE platform provides a collaborative engineering methodology that captures, manages and tracks product requirements with complete traceability.

Full traceability

Garakh finds the 3DEXPERIENCE platform’s RFLP (Requirements, Functional, Logical and Physical) approach a competitive advantage because it provides a collaborative engineering methodology that captures, manages and tracks product requirements with complete traceability. “A project manager can set functional and logical specifications for the rolling stock, define requirements and then connect it all to specific physical models,” Garakh said. “In this way, we create a three-dimensional end-to-end design ranging from specifications to final product, which eliminates data loss and ensures traceability throughout the entire process. It also reduces the need to make modifications to the product at later stages, where it can cause a lot of problems.”

Yunitski’s faith in the future of transportation is solid. “Unlike Henry Ford whose dream was to have highways encircle the planet, my dream is to make safe, cost effective and environmentally-friendly string roads operating on every continent and encircling the globe. It is what has inspired me to create Unitsky String Technologies, Inc.. I am confident about the success of our project because we are creating a perfect means of transportation, which is demonstrated in our EcoTechnoPark in Maryina Gorka (approximately 63 km south-east of Minsk) where we have already built four test sections that meet all the requirements I’ve mentioned earlier and that are superior to other known transportation systems in existence today. As a matter of fact, four of our vehicle models have already been certified by the Russian authorities.”

Focus on Unitsky String Technologies, Inc.

Engineering company engaged in project design, construction and promotion of high-speed (up to 500 km/h) urban and freight transport systems.

Products: High-speed intercity, urban passenger, cargo and lightweight touring vehicles

Headquarters: Minsk, Republic of Belarus

For more information: www.unitsky.com

Focus on IGA Technologies CJSC

IGA Technologies CJSC is a Russian company providing professional consulting in product lifecycle management. The company sells, provides technical support as well as consulting and maintenance services for the deployment, configuration, and implementation of the full portfolio of Dassault Systèmes software applications in the Russian Federation and CIS countries. The company has a high level of expertise in leveraging PLM applications in the shipbuilding, rocket and space, as well as energy and engineering industries.

For more information www.igatec.com