NASA’s Kennedy Space Center manages and operates America’s astronaut launch facilities, including the ground operations needed to prepare for each program. Engineering teams working on projects such as the Space Shuttle, the International Space Station, or the Launch Services program are responsible for designing components and making them become a reality. Since each project is highly unique, the Design Visualization Group is called upon to perform lifelike 3D simulations before any ground work occurs. The group simulates projects within Dassault Systèmes DELMIA to make sure operations are feasible, efficient and safe.

NASA’s Kennedy Space Center: Visualizing the Possibilities

In 1961, President Kennedy set the goal of landing a man on the moon within the decade, and by December 1963, the installation that was built to help achieve this dream would bear his name. The facility now known as the John F. Kennedy Space Center (KSC) has been the launch site for U.S. human space flight since 1968. KSC has evolved over time to meet the changing needs of America’s space program and has controlled launch operations for lunar exploration, the Space Shuttle Program and current work on the Launch Services Program.

For nearly half a century, NASA has built dozens of processing facilities within KSC to support its various programs. These facilities are used to integrate and test rockets, capsules, launch pads and components of many projects. Starting with the early stages of its design cycle, Kennedy Space Center’s Design Visualization Group is called upon to determine precisely how things will be assembled using the facilities and resources at its disposal.

Simulation to ensure feasibility, safety, efficiency and cost effectiveness

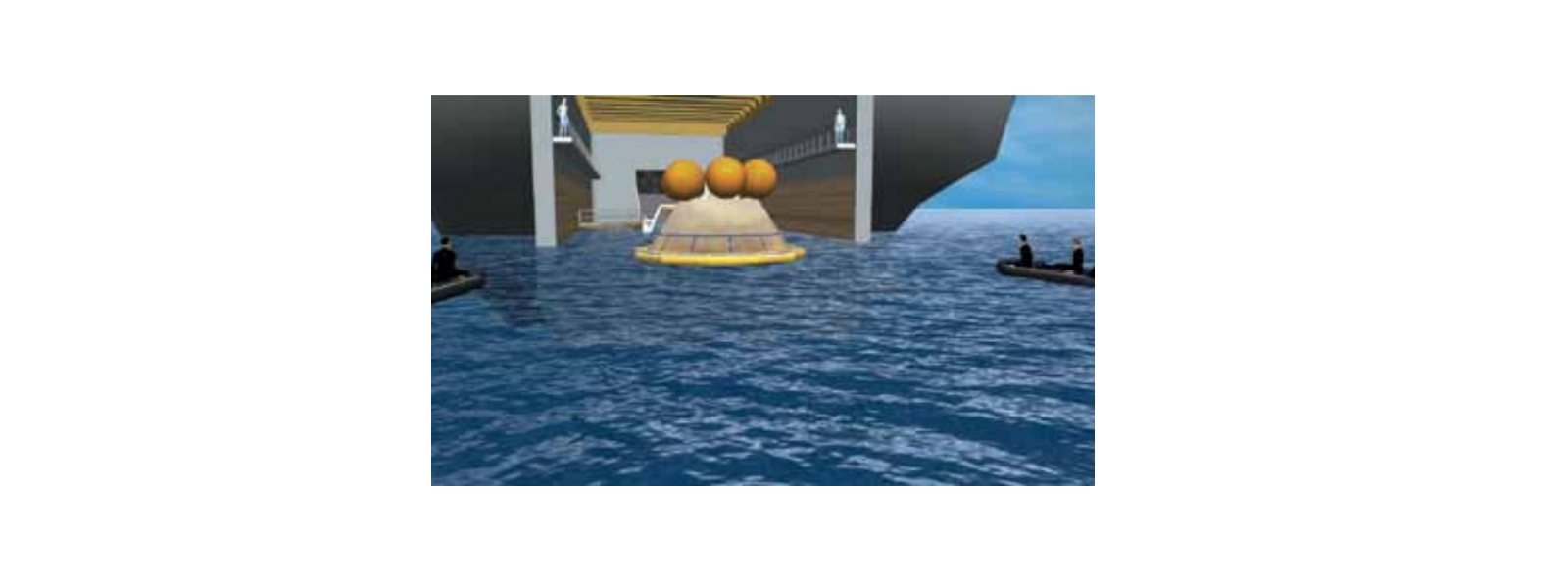

The Design Visualization Group, a ten person Civil Service and Boeing team led by NASA veteran Tracey Kickbusch, simulates ground operations before they occur in order to ensure that projects are not only feasible, but carried out safely, efficiently and cost effectively. To do this, they use the 3D virtualization capabilities of Dassault Systèmes DELMIA. 3D virtual models have been built within DELMIA for approximately 20 different facilities at KSC, along with thousands of models for ground support equipment including transporters and fixtures for rotating and assembling parts.

For example, KSC’s iconic Vehicle Assembly Building (VAB), one of the largest buildings in the world by volume, was originally built to allow for the vertical assembly of the Saturn V rocket for the Apollo program. More recently, it has been used for housing external fuel tanks and flight hardware, and is the location of space shuttle orbiter mating (stacking) with the solid rocket boosters and external fuel tank, that combined makes up the complete space shuttle. These types of complex activities occur all across Kennedy Space Center. With so many moving parts, all of them very high dollar, one of a kind systems, NASA engineers need to understand how all of the equipment and operators will work together to accomplish certain tasks, and virtual simulation within DELMIA is key to achieving this directive.

The Design Visualization Group is responsible for evaluating predictable processes like the mating of the LRO/LCROSS spacecraft and its fairing, but is also called upon to consider unlikely scenarios so NASA can be prepared for even the most improbable occurrences. For example, a large hoister used to lift the shuttle orbiter into its vertical launch position and to join the fuel tank is controlled by a person sitting atop the fixture. The Design Visualization Group simulated the stacking procedure to make sure the plan was feasible and cost effective, but it was also tasked with simulating scenarios for specific safety procedures. In this case, the group was asked to determine a course of action should the operator of the hoister be stricken with a heart attack while behind its controls.

Common terminology through lifelike simulation with DELMIA

Engineering teams from various projects meet with the Design Visualization Group on a regular basis to review proposals for how their designs become a reality. In the past this process was hindered by the need to rely on verbal descriptions, which can be an inefficient method to communicate complex projects. Because of varied terminology, a large team with a diverse background and thousands of potential assets, relying solely on verbal descriptions could sometimes present an effective communications challenge. However, with the lifelike simulations in DELMIA, everyone can actually see and understand what is being proposed, and engineering teams can be provided with videos and DVDs of the simulation to accompany the final ground operations processing documents.

This is an important element of design optimization. In fact, during the planning stages for Constellation, areas were identified that would not be accessible to technicians in their safety apparatus during contingency operations. The Design Visualization Group was able to send images to the Orion designers and enlarge a hatch opening to allow the work to occur. This capability has been so well received that it will continue in the future. The former Program Manager, Jeff Hanley, was so impressed with the videos that were created from the Ground Operations Simulations that he requested they be put on YouTube.

DELMIA allows the Design Visualization Group to import CAD data directly from engineering teams, and with its support for STEP—an open file format—the data can come from whatever CAD system the engineering team chose to use. A complete design is imported into DELMIA down to each last nut and bolt, and powerful features enable the team to view objects in their entirety—as they would look in real life—or to drill-down and view specific components.

Laser scanning improves accuracy

Once a design is imported into DELMIA, the team utilizes its 3D library of facilities and support equipment to visualize and simulate a project. To ensure that the 3D library is properly maintained, and that each 3D model is a true representation of the real-life facility, the team relies on laser scanning. For example, if the team chooses to use a platform that has not been in service for a few years, it could be scanned to validate or update the 3D model to account for any sagging that may have taken place.

Another situation where laser scanning proves invaluable is when the team has to add equipment to the library. In this instance, they may have to rely on blueprints older than they are. Furthermore, the equipment being used will likely have had thousands of engineering orders since its creation. Instead of tracking the changes made through those orders over time, laser scanning is an efficient method to create a true 3D representation of the equipment. Most newly developed assets have CAD data available that can be easily imported into DELMIA, but laser scanning gives a renewed life to older assets, enabling them to be tested within a virtual environment for situations where they might once again be needed. In addition to the inherent values of virtual simulation, the ability to reuse older assets, with the help of laser scanning, is one more way it can increase efficiency and reduce costs.

As the U.S. space program evolves into its next phase of exploration, Kennedy Space Center will play an important role. NASA engineers, including those at KSC, have always been at the forefront of technological innovation and their use of 3D simulation will continue to be an invaluable tool that brings efficiency, safety and cost savings to projects at NASA. Innovations like 3D simulation that have been pioneered by Dassault Systèmes will set the bar high as space exploration begins to take hold in the private sector.