LEADING ENVIRONMENTAL AND TESTING SOLUTIONS

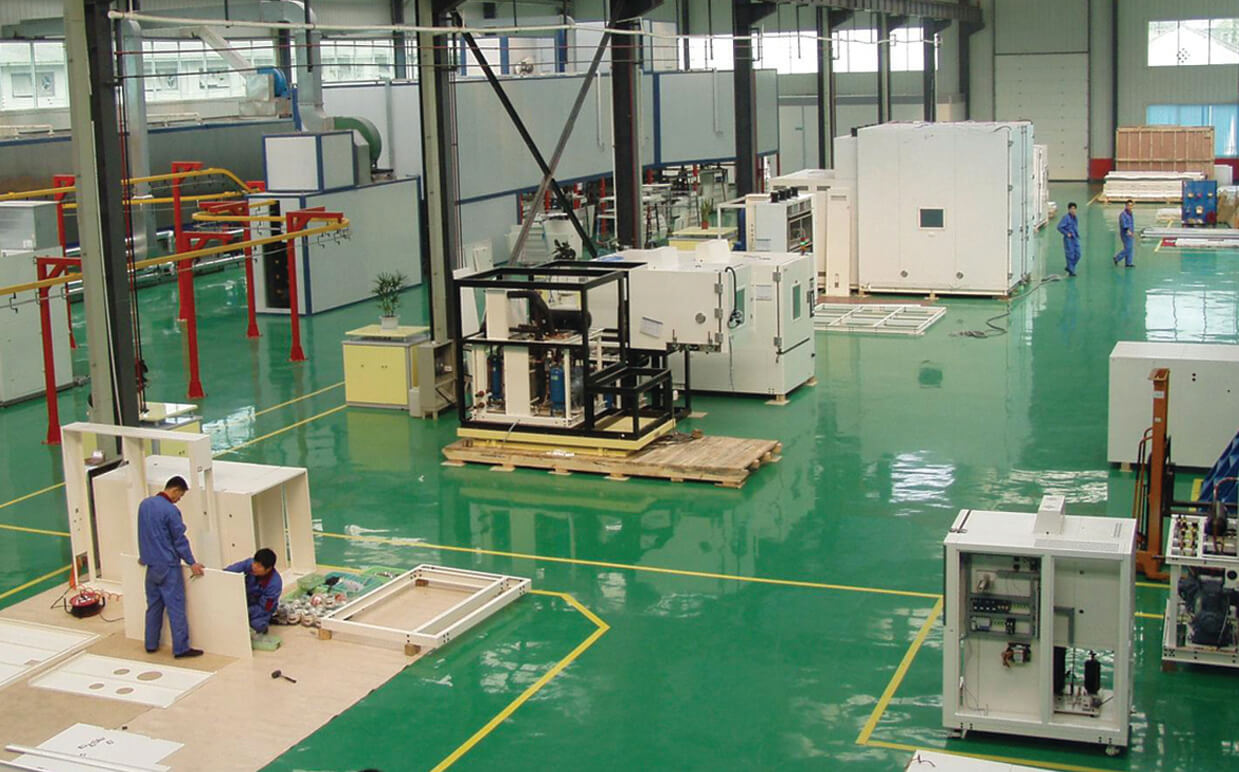

Founded in 1966, Chongqing Yinhe Experimental Equipment Co. Ltd (CQYH) is China’s leading research organization that develops and manufactures environmental and reliability testing equipment in series as well as tailored to specific customer requirements. Positioned among the top three environmental instrument manufacturers on the world market, its equipment is used by companies in the military, high tech, aerospace and automotive sectors around the world.

Experiencing increasing pressure from European and Asian competitors, CQYH realized that the only way to stay ahead is to improve development efficiency and to create a better user experience with its products. Its strong sense and understanding of innovation, as well as the firm determination of its employees to “create a 100-year business” prompted CQYH to focus on creating products that promote the sustainable growth of its customers.

INNOVATING WITH TECHNOLOGY

One area that the company wanted to reengineer was its order fulfillment cycle, which was necessary to accelerate delivery of products tailored to customer requirements. This meant reorganizing the architecture of its products by adopting a more modular approach to development. As products become more complex and the number of components rises, CQYH needed to develop more specialized products without driving up costs due to this diversity. The solution they chose was to use a limited number of parts to produce a wide variety of products.

To support this strategy, the company chose Dassault Systèmes’ 3DEXPERIENCE platform® and its Simple Solution Selection industry solution experience to benefit from predefined modules to develop its products. “The Product Architecture Management module from Simple Solution Selection is used to create modules, module variables and interfaces between modules,” Zhang Zhixian, CEO of CQYH said. “We also use the Single Product Configuration feature for BOM (bill of material) and 3D creation and order-driven configuration management. Not only does the Dassault Systèmes’ 3DEXPERIENCE platform help us to streamline existing processes and improve our market responsiveness and efficiency, it provides customers with the most intuitive 3D experience as well, which helps them to quickly make the right decision through CQYH’s order response system. This is one of the main reasons we chose the 3DEXPERIENCE platform.”

Each CQYH product evolves as a highly complex systems engineering process, which covers strategy development, customer requirements management, defining the right price, product definition, platform selection, module design and manufacturing verification. “With Simple Solution Selection, our order management has gradually transitioned to a module-driven configuration management model, effectively improving our order processing efficiency,” Zhixian said.

With Simple Solution Selection, our order management has gradually transitioned to a module-driven configuration management model, effectively improving our order processing efficiency.

CUTTING ORDER FULFILLMENT AND DESIGN ERRORS IN HALF

“Before we began using the 3DEXPERIENCE platform, when customers provided us with their requirements, we would go through many stages to make a proposal, submit this proposal to the customer and after a period going back and forth and making modifications we would finally deliver the finished proposal to the customer. The entire process would take quite a long time,” Zhang explained. “Now with the 3DEXPERIENCE platform, we can directly input customer requirements and display them in a 3D model. If this 3D model is what the customer wants, they can instantly confirm it and the product would be submitted for production. This has essentially eliminated the need for physical prototypes for customer review, which has accelerated order fulfillment by 50%. In the past, we would sometimes have a different understanding of what customers wanted, which resulted in a product that didn’t respond to their specifications. It would have to be reworked, which generated errors and delayed product delivery. With Simple Solution Selection, we reduced design errors by 50%,” Zhang said.

“Moreover, our R&D activities have become better organized and although the number of newly developed parts is falling, the number of orders keeps going up,” he continued. “We’ve increased our turnover from RMB40 million to RMB150 to 180 million since we’ve implemented the 3DEXPERIENCE platform. One obvious benefit is the significant improvement in customer confidence and recognition that our core skills have improved, enabling us to successfully compete on an international scale,” Zhang said.

The 3DEXPERIENCE platform is currently being deployed at CQYH in three stages. ”The first stage dedicated to building the product architecture is practically completed,” Zhang said. “The next stage is to deploy a project management and digital spare part management system, which we expect to complete by end of 2016. We will continue our development as a leading manufacturer and provider of climate and environmental solutions and we hope to make a breakthrough in the North American market as well.”

With Simple Solution Selection, we accelerated order fulfillment and reduced design errors by 50%.”

Focus on Chongqing Yinhe

Designs and manufactures environment and reliability test equipment

Products: temperature testers, pressure testers, resistance pressure testers

Employees: 150

Revenue: €24.3 million

Headquarters: Chongqing, China

For more information www.cqyhyq.com/en/

Focus on RP Technology

Beijing RP Technology Incorporated specializes in providing digital technology and professional services to global manufacturing users. Focusing on Product Lifecycle Management (PLM), it offers IT solutions, system integration, technical support and professional engineering services to users in automotive, aerospace, electronics and electrical appliances, universal equipment, shipbuilding and construction industries. RP Technology has sales and technical support offices in Beijing, Shanghai, Changchun, Chongqing, Guangzhou, Wuhu and Fuzhou.

Since its establishment in 1998, RP Technology has been a long-term partner of Dassault Systèmes. Currently the company employs more than 70 engineering technicians, professional consultants and industry experts.

For more information www.rp-tech.com.cn