Bureau Veritas / Naval Group

Bureau Veritas and Naval Group joined their forces to develop the 3D Classification concept based on the 3DEXPERIENCE platform to reduce design review times of new ships and the inherent costs.

Entering a new age

For ship owners and operators, safety and efficiency are of the utmost importance. Inefficient design and construction can result in high operating costs, increased fuel consumption and a shorter operating life. Today, more and more shipyards are modernizing their operations by taking advantage of digital transformation to increase their efficiency and quality as well as reduce costs. Naval Group, the European leader in the naval industry, is one of these companies having chosen 3D models as the standard for their activities.

“To meet our business challenges, innovation is at the heart of our strategy,” said Olivier de la Bourdonnaye, executive vice president Industry, Naval Group. “Innovation in product, but also in processes. It will help us to decrease our engineering costs and also improve the lead time of our developments.”

To ensure ships comply with safety and environmental regulations before they are set out to sea, ship designs and production facilities are tested, inspected and certified by independent classification societies like Bureau Veritas, a global leader in this domain. “To remain competitive, we need to review our business model to improve productivity,” said Matthieu de Tugny, president, Marine & Offshore, Bureau Veritas. “Proceeding with our digital transformation and focusing on the life cycle management of the products we certify are our main priorities. We are leveraging our digital initiatives to better respond to our customers’ expectations and to improve our own operational excellence.”

3D Classification based on the 3DEXPERIENCE platform will help us decrease our cost of engineering and also improve the lead time of our developments.

Challenging processes

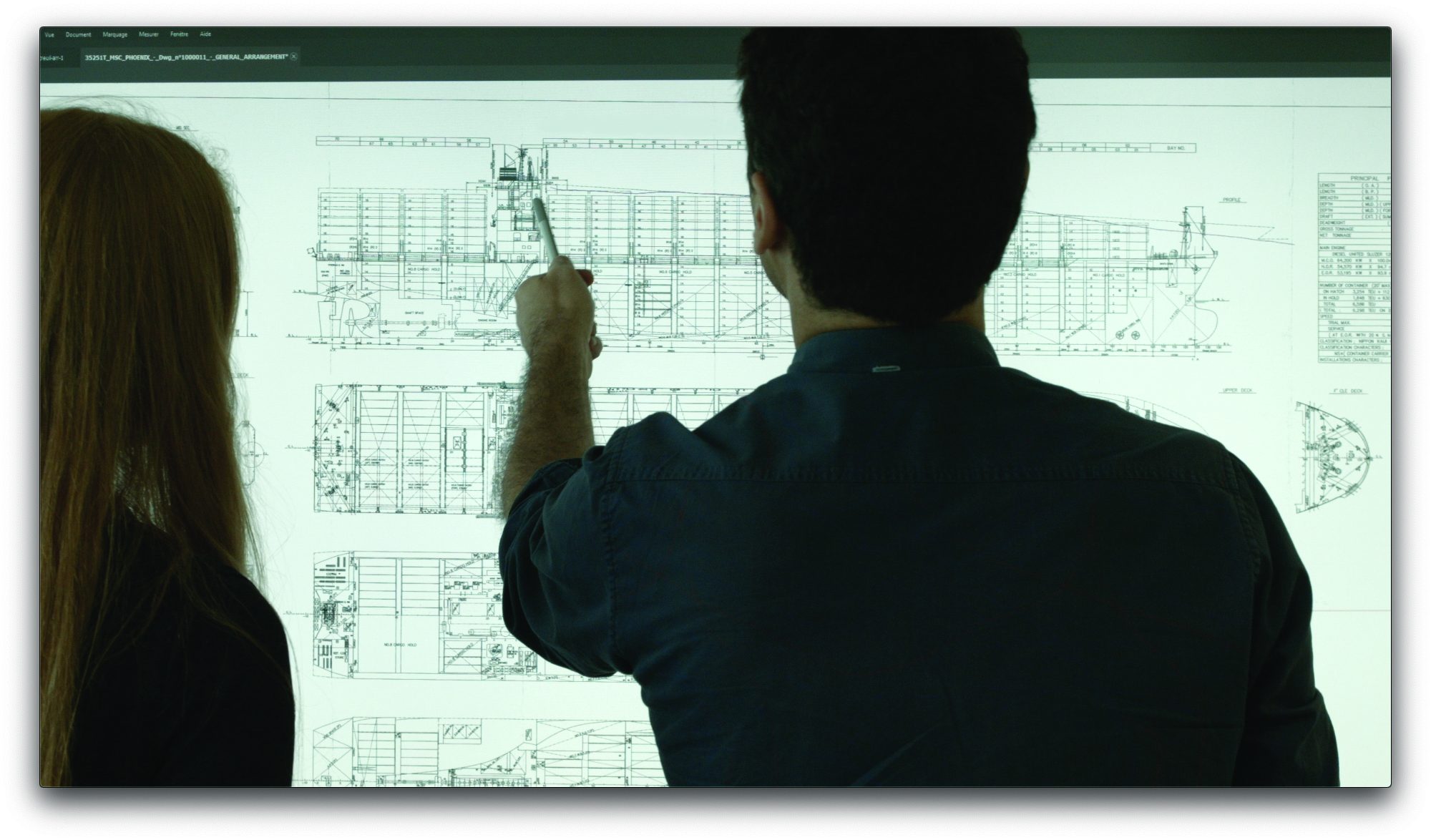

Design review is a key phase in the classification process. Facing limitations with the standard classification process of vessels based on 2D drawings, Bureau Veritas and Naval Group joined forces to define pragmatic solutions that would enhance the competitiveness of both companies.

“Classification is an iterative process,” said Cédric Cheylan, manager of the hull structure design team at Naval Group. “First, we design the structure in 3D, and then we create 2D plans for Bureau Veritas to inspect and return to us with their comments. We then either decide to provide further justification, or to update the model in 3D and start a new loop. Managing the inconsistencies that can arise between 3D models and 2D plans is difficult and time-consuming. There is a risk of misunderstandings between Bureau Veritas and Naval Group.”

“The standard classification process based on 2D paper drawings brings two main limitations,” explained Jean- François Segretain, marine technical director at Bureau Veritas. “Finite element calculation models are generated from these drawings to perform the necessary analyses. Unfortunately, there is no direct link between the calculation models used by the classification society and the drawings. Plus, it’s sometimes difficult to see the geometry of a complex shape using only 2D drawings.”

“Instead of reviewing a collection of 2D drawings, we are now delivering the classification based on the 3D model of the vessel,” de Tugny said. To meet this challenge, Bureau Veritas is operating the 3D Classification process on a classified navy ship designed by Naval Group.

3D Classification brings practical, tangible and scalable benefits to the shipbuilding industry.

Fostering digital continuity

Bureau Veritas and Naval Group are leading the charge in the development of the 3D Classification concept based on Dassault Systèmes’ 3DEXPERIENCE platform. The main driver is to accelerate the classification process by transitioning from 2D to 3D.

“With 3D Classification, we will provide Bureau Veritas with a 3D digital model, which eliminates the need to create 2D plans,” Cheylan said. “Implementing end-to-end digital continuity between our two companies will provide benefits in terms of time and costs as well as lead to a better technical understanding.”

“We are relying on the 3DEXPERIENCE platform to push this new classification approach based on a 3D model of the vessel forward,” de Tugny said. “Not only will we reduce the number of iterations and the time spent to certify a design, the different stakeholders also can better share information and connect data on this platform to our different calculation tools, which will improve accuracy and traceability.”

“Moreover, we can automatically generate our calculation models from the 3D digital mockup, which saves time and resources,” Segretain added.

The 3DEXPERIENCE platform offers a number of features that make 3D Classification possible. With filtered information based on roles, Bureau Veritas and Naval Group can ensure confidentiality and IP protection when sharing models with each other. They can directly integrate comments on the 3D model and manage revisions by enabling easy visualization of modified areas while keeping track of revision history. They can link design and classification models throughout the lifecycle of a vessel. And it is easier to keep track and update information since they work from a single data source.

Tailored to the shipbuilding industry

Through the work accomplished as part of the collaboration, Dassault Systèmes enhances its offering with a readyto- use certification solution for the shipbuilding industry. By providing a replicable structure for shipyards and classification societies, including industry methods and best practices, the solution connects the dots for a streamlined design-to-certification process.

“3D Classification brings practical, tangible and scalable benefits to the shipbuilding industry,” de Tugny concluded.

Focus on Bureau Veritas

World-leading testing, inspection and certification company.

Products: Services to help companies fulfill their quality, safety, environmental protection and social responsibility obligations

Revenue: 4.8 billion Euros (2018)

Employees: 77,000

Headquarter: Paris, France

For more information www.bureauveritas.com

Focus on Naval Group

Leading European design, manufacturing and service company of naval submarines and surface ships.

Products: Submarines, surface ships, weaponry, surveillance and intervention solutions, marine renewable energies

Revenue: 3.7 billion Euros (2017)

Employees: 13,429

Headquarter: Paris, France

For more information www.naval-group.com