SHoP Architects

SHoP adopted Dassault Systèmes’ 3DEXPERIENCE platform on the cloud and its Design for Fabrication industry solution experience to design and coordinate global stakeholders on its projects.

There are many ways to express innovation. For an architectural firm like New York-based SHoP Architects, it means harnessing the power of diverse expertise in the design of buildings and environments to improve the quality of public life. “Architects want to delight people with their designs,” Chris Sharples, founding partner at SHoP Architects, said. “This is why we focus on first understanding what our clients want, what function a building will serve and imagine a design that will help them achieve that.”

SHoP does not only focus on designing buildings; the company also is involved in public works, entire infrastructures, and cultural as well as institutional projects. “We constantly seek innovative ways to build by using traditional materials like wood and prefabricated or modular systems for high-rise construction,” Sharples said. “We are currently working on some exciting projects like a very tall residential tower in midtown Manhattan that we are dressing in beautiful terra cotta and bronze. Another project is a complex of two adjoined buildings in San Francisco, California’s Mission Bay neighborhood that will contribute to transforming this developing stretch of Mission Bay into a dynamic, pedestrian-friendly neighborhood. It’s our way of demonstrating how innovative architecture can play an important role in transforming a community.”

Iconic symbol of diversification

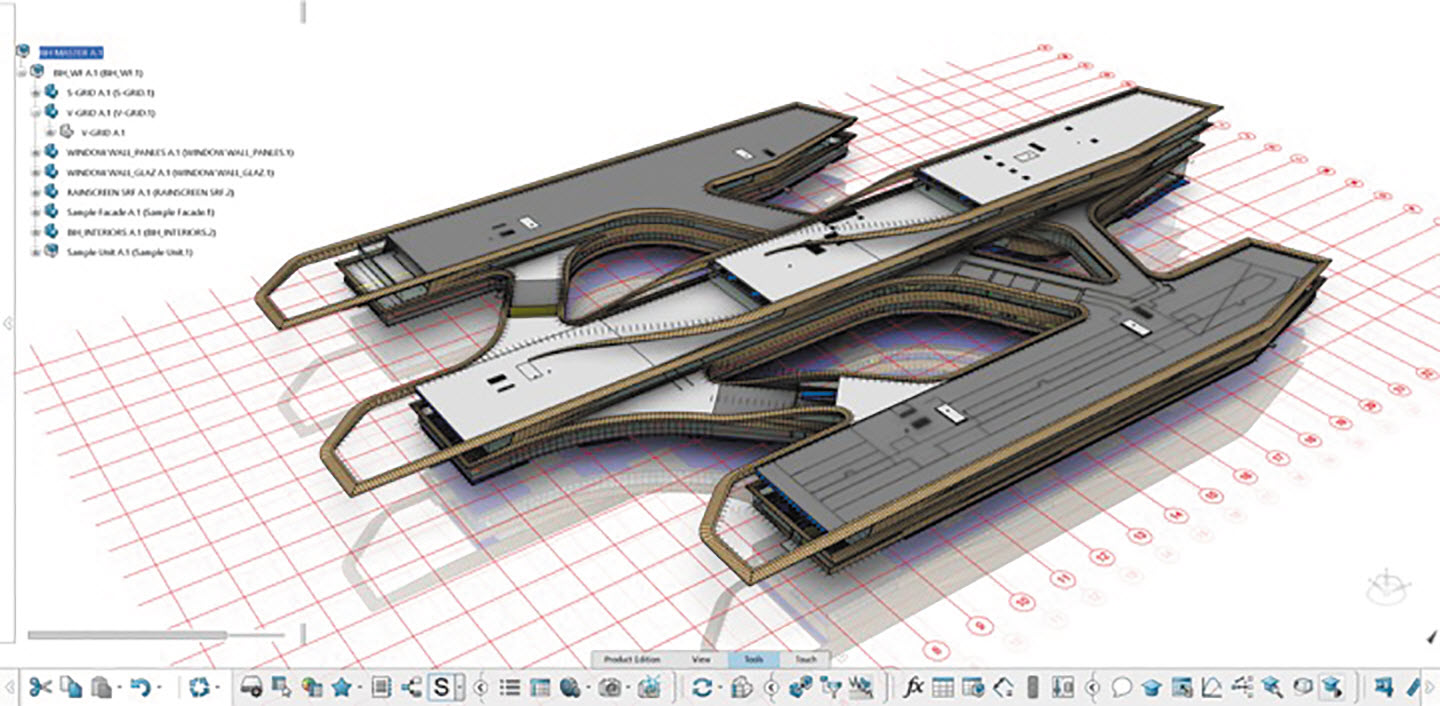

Another of the firm’s iconic projects, currently under construction, is the Botswana Innovation Hub in Gaborone, Botswana. “The Innovation Hub is a government-driven initiative to support innovation in research and development and entrepreneurship in the region,” John Cerone, associate principal at SHoP Architects, said. “It is a huge investment for the Botswanan government to diversify its economy and to move from one primarily based on diamond extraction toward a more knowledge-based economy,” Sharples added. “Our client expressed a desire for a timeless building that features the latest advances in green technologies,” Cerone continued. One of the systems SHoP developed is an energy blanket rooftop that combines sustainable energy techniques and large overhangs to passively shade the building’s interior. The Innovation Hub is also equipped with mechanisms to collect and re-use water, and passive and active photovoltaic systems to harness solar energy. “One of the biggest challenges we faced is managing the graceful, morphing shape of the building and the many different parts, which are fabricated in Cape Town, South Africa, that are required to achieving this flowing structure,” Cerone said. “There are many variables and tolerances are very tight. It requires a high level of control and the ability to coordinate the fabricator and the construction site, both thousands of miles away from our design offices in New York.

”The Botswana Innovation Hub façade was entirely designed for construction with Design for Fabrication and the 3DEXPERIENCE® platform. “We used the 3D modeling application CATIA and the collaboration application ENOVIA on the cloud for this project,” Cerone said. “We would not be able to attain the level of control and detail required to complete this project without the 3DEXPERIENCE technologies.” Since the cloud operates 24/7 365 days a year, it makes collaboration easier as stakeholders are on different schedules and time zones. “We’re coordinating people across the globe in real time,” he continued. “It is a completely different way to engage a project as it contextualizes every aspect into a holistic approach.”

SHoP has, in fact, been using the 3DEXPERIENCE platform on the cloud for more than three years, and was one of the first customers to use the platform as part of Dassault Systèmes’ Lighthouse program. The firm realized during that time the value of working on the cloud and decided to continue using it on new projects. “On the cloud, everyone has instantaneous access to the most up-to-date information,” Sharples said. ”It creates a sense of order because it’s not in somebody’s drawer somewhere; it builds a shared experience.”

The 3DEXPERIENCE platform enables for this evolutionary process because it is a flexible and open platform. And what’s great about it is it not only covers design and construction, it covers a building’s entire lifecycle. It’s sustainable innovation.

Seamless Relationships

The 3DEXPERIENCE platform is helping remodel the architectural design process. “Our favorite aspect about the 3DEXPERIENCE platform is its vision and the positive effect it has on our industry,” Cerone said. “Generally, in architecture, there are many workflow inefficiencies, in the way disciplines, owners and trades interact with one another. A lot of time and effort is spent communicating intent between parties. With technology evolving all the time and computer processing power getting better, it is becoming more realistic to do real-time simulations and collaboration. The 3DEXPERIENCE platform allows for more seamless communication.”

Sharples believes that architects should think more like manufacturers and to try to pull as much off the construction site by getting things prefabricated and manufactured in a controlled environment and then assembling the modules on site. “Of course, we can approach projects in the traditional way but I think we can really blow the doors off the barn by taking advantage of a modular approach, which is very well developed in the 3DEXPERIENCE platform,” he said.

He also believes in the power of technology and the determining role it has on the way his firm’s practice has evolved. “One of our biggest challenges is moving from the traditional way of working using plans and sections – dealing with space and all the things that go into a structure like air flow and environmental controls – to working with 3D models,” Sharples said. “A traditional plan and section approach often leads to misunderstandings when presenting information to clients, consultants or to the build team. Working with 3D models that represent all aspects of a design from a structural, mechanical and systems point of view enables us to manage that complexity in a more collaborative way. We can then create a more seamless relationship between all the different disciplines that go into constructing a building. Working with 3D models can improve the way we design and communicate because it is more open and transparent."

Managing a building's lifecycle

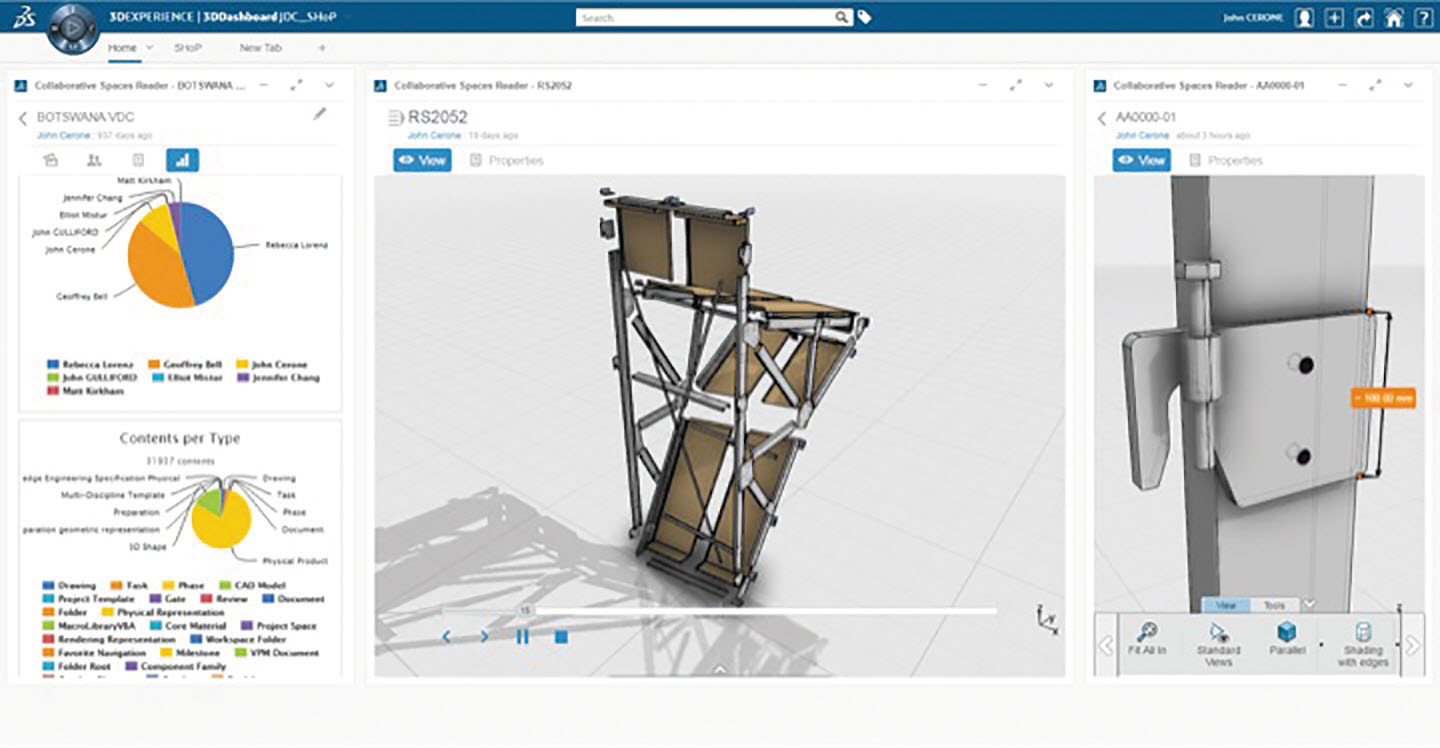

Design for Fabrication also enables SHoP to design from ideation to the components and assemblies all the way through to developing the systems and eventually to the fabrication of the systems that will be installed in a building. “We can track that same information all the way though its lifecycle, which provides us with end-to-end traceability,” Cerone said. Moreover, 3DEXPERIENCE has delivered a level of efficiency to SHoP’s workflow, which just didn’t exist before. “People are engaging the project at the concept level and watching it mature through its lifecycle,” Cerone continued. “The 3DEXPERIENCE platform powered by ENOVIA allows us to create a social and collaborative environment around our projects. Anyone, with or without design experience, can access 3D representations, associate that with information posted on the platform by other disciplines, and create interrelationships between scheduled tasks and geometry. It allows more stakeholders to engage in the design process, which has changed the way we approach new projects. We find enormous benefit leveraging this technology at the conceptual level and seeing our concepts grow as we explore different options along the way. It’s a real eye-opening experience.”

SHoP uses the 3DEXPERIENCE platform’s live dashboarding capabilities with ENOVIA to allow people with specific roles and interests to participate in the project at various stages and maturities. “Stakeholders can tailor their dashboards so that they have a real-time view of the aspects of the project that interest them and to make informed and rapid decisions on issues as they arise,” Cerone said.

To continue pushing the envelope of the 3DEXPERIENCE platform, SHoP receives services and support from Vancouver-based CadMakers Virtual Construction, a Dassault Systèmes certifi ed business and education partner. “CadMakers is much more than ‘resellers’ of Dassault Systèmes’ solutions – they are power-users that approach problem-solving with an intimate working knowledge of our industry,” Cerone said. “They feel like an extension of our team, and their support has been focused and impeccable.”

Reducing time with design templates

The company capitalizes its know-how and design practices with reusable templates in Design for Fabrication. “Our designs often involve unique components, which would increase complexity and a duplication of information that could be a challenge to manage conventionally,” Cerone said. “We can demystify design complexity by capturing our knowledge in templates and using them when similar concepts arise from one project to the next. Concept and deliverables are of course unique to every project, but preserving the process in templates is invaluable for efficiency.”

On the Botswana project, in addition to templates, SHoP relies on 3D to accelerate the design to manufacturing process. “We’re going directly from digital model to fabrication,” Cerone said. “The machines develop NC code directly from our CATIA models for the fabrication of the Innovation Hub’s façade. And since everything is on a single platform, there is no loss of information because we don’t need to transfer data to and from heterogeneous systems. It’s all compatible and in one place.”

“If you look back to the renaissance or gothic periods, those who designed and those who built worked together,” Sharples said. “Ironically, designers weren’t using drawings in most cases, they were using models to explain the design to the craftspeople, who would look at those models and then climb up on the scaffolds to start building. What the 3DEXPERIENCE platform does is it allows for that kind of collaboration to happen, starting at the predesign stage and watching the model, which is actually organic, alive and changing, grow through to construction or manufacture. The 3DEXPERIENCE platform enables this evolutionary process because it is a flexible and open platform. And what’s great about it is it not only covers design and construction, it covers a building’s entire lifecycle. It’s sustainable innovation.”

Focus on SHoP Architects

Based in New York City, SHoP Architects is a world-renowned design fi rm founded in 1996. SHoP aims to harness the power of diverse expertise in the design of buildings and environments that improve the quality of public life.

Products: Architecture, interior design, planning, direct-to-fabrication, delivery and envelope engineering

Employees: 180

Headquarters: New York, New York, USA

For more information: www.shoparc.com

Focus on CadMakers Virtual Construction

A Dassault Systèmes partner based in Vancouver, Canada, CadMakers Virtual Construction is an integrated construction technology company focused on applying manufacturing and automation processes, people and technology to the construction industry.

For more information www.cadmakers.com